Access to the Most Sophisticated Testing and Analysis Equipment

At Fulton Bellows, we recognize that our customers have unique and diverse requirements when it comes to the quality and performance of our bellows. To ensure that we meet and exceed these expectations, we offer a comprehensive range of testing capabilities that allow us to thoroughly inspect and validate our bellows and assemblies.

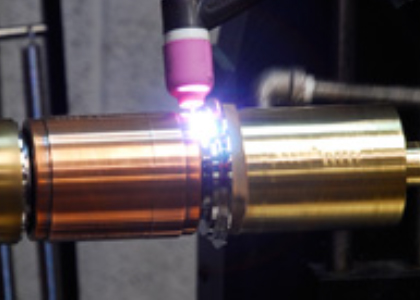

Fulton is fortunate to be located near the flagship campus of University of Tennessee, in Knoxville. We are able to leverage access to world class faculty, students and facilities as required for assistance solving complex challenges related to manufacturing processes and materials.

Our testing capabilities encompass a variety of methods that are tailored to specific requirements and industry standards. From basic dimensional inspections to more advanced performance evaluations, we have the tools and expertise to ensure that our bellows and assemblies meet the strictest quality benchmarks.

For dimensional inspections, we employ high-precision measurement equipment that enables us to verify critical dimensions, tolerances, and geometries with utmost accuracy. This meticulous approach ensures that our bellows and assemblies are manufactured to precise specifications, promoting optimal fit and function within various applications.

To assess the performance characteristics of our bellows, we employ a range of specialized testing methods. These include pressure and leak testing, fatigue testing, vibration testing, and thermal cycling, among others. Through these rigorous evaluations, we can assess factors such as pressure resistance, durability, fatigue life, torsional stiffness, and operational reliability. This extensive testing regimen guarantees that our products can withstand the demanding conditions they may encounter in real-world applications.