Our Thermal Actuators Thermostats are Custom Engineered for Your Application Requirements

Fulton Bellows has over 50 years of experience manufacturing thermal actuators. This vast history provides us a broad range of knowledge of thermal actuator performance and durability characteristics. Our product engineers are available to collaborate with you to develop thermal actuator solutions from the most basic of applications to those that are extremely complicated and unique. Our technical team will work closely with you throughout all stages of your product development, from conceptual stage through production.

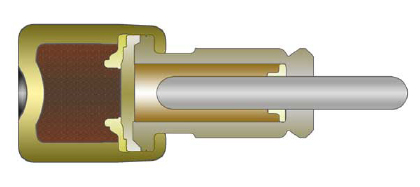

Thermal actuators are a compact, rugged and dependable power source. They can quickly transform heat energy into piston-driving mechanical energy. Fulton Bellows manufactures thermal actuators in many configurations, but all have two things in common – they operate very rapidly at specified temperatures, and they are reliable over a long lifetime.

A return load must be provided for proper thermal actuator operation. This load should typically be 10 lbs. minimum and 25 lbs. maximum. Although pressure changes do not affect the thermal actuator characteristics, stem loading does.

Return springs opposing stem movement should be selected to provide the minimum return loads listed above at minimum temperatures. Spring rates generally should be as low as possible, since life expectancy is dependent on the maximum load to which the thermal actuator is subjected. In no case should the maximum load be exceeded (including the over-run).

The typical working stroke of Fulton’s thermal actuators is either .140” minimum or .260” maximum, depending on cup configuration. In some instances, working strokes can be obtained within a temperature range of 10°F, or as great as 100°F, most commonly over a 20°F range.

Capabilities

Certified Processes

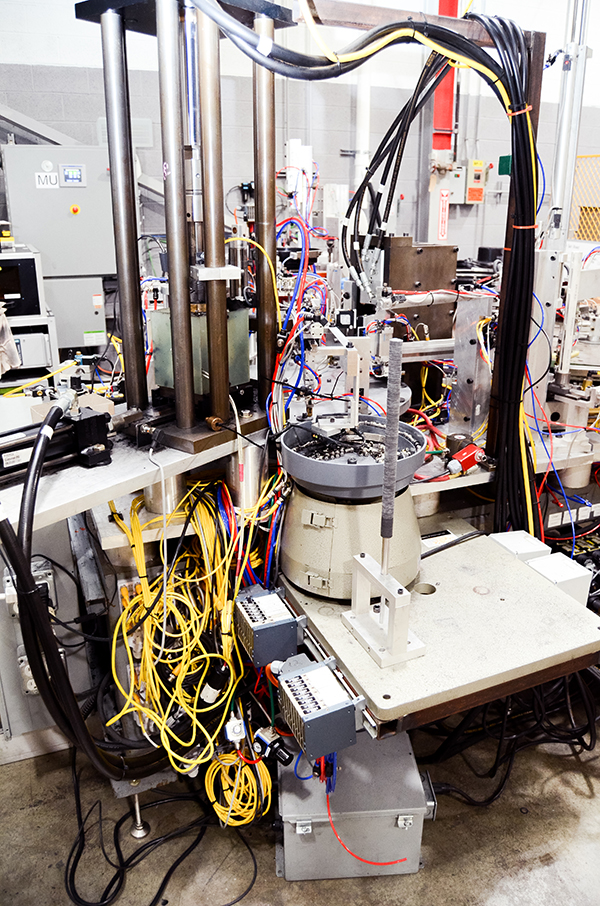

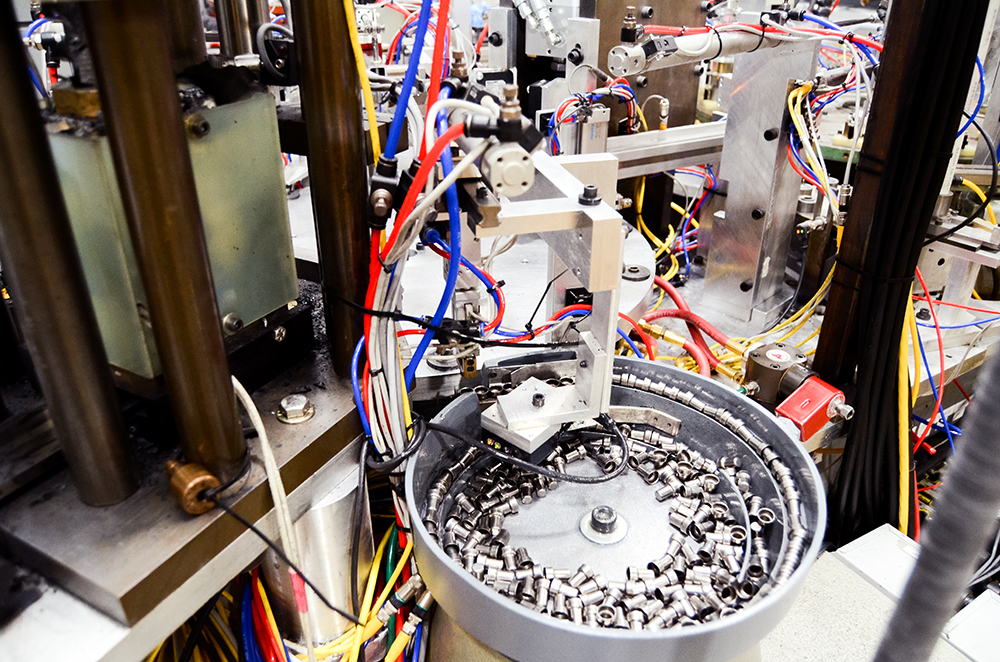

Utilizing both in process and end of line testing, Fulton Bellows ensures that your product meets your specifications. Our testing regimen includes: