Providing Bellows Solutions for a Variety of Applications, from Basic to Complicated

Our design engineers are able to produce a bellows solution for the most basic applications, to those that are extremely complicated and unique. We are able to provide you these solutions supported by life test data and years of excellent field performance. The metal bellows solutions are used in many technology sectors, such as to regulate pressure and temperature in aerospace and automobile applications, heating systems, medical equipment, gas turbines, oil and gas exploration, seals for industrial valves, and electrical equipment. Several types of bellows are available from Fulton Bellows.

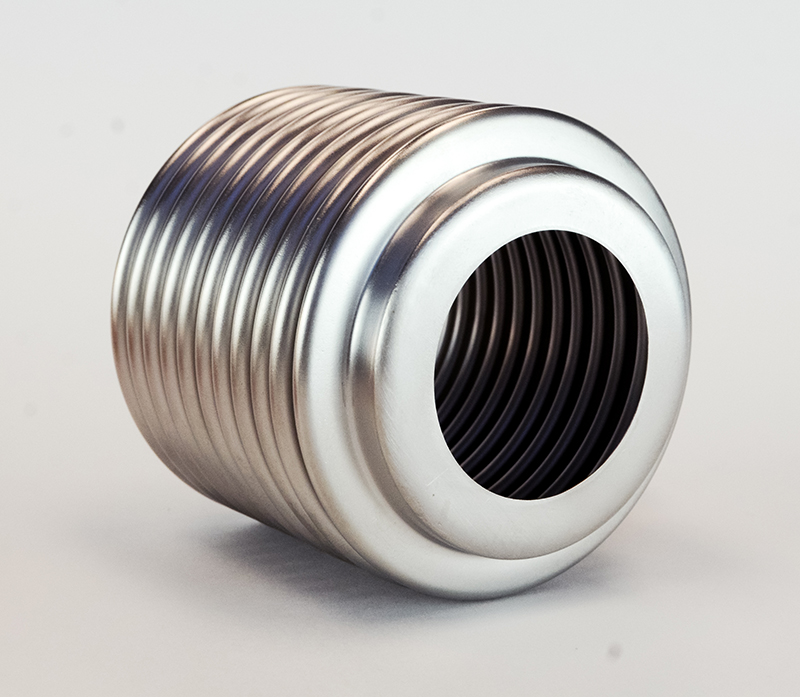

Standard hydroformed bellows are the most economical bellows to choose. They are characterized by the root diameter being equal to the tube diameter. Standard Bellows can be formed using seamless drawn tubing or seam-welded tubing. If using seamless drawn tubes through tooling adaptations, modified shapes and diameters of the finished bellows ends can be formed as part of the corrugating operation. Bellows with an integral bottom can be formed by retaining the closed tube end as part of the finished product. This technique often avoids the need for a separate end fitting.

A precision-made tube is placed inside a movable set of forming plates in a hydraulic corrugating machine. Hydraulic pressure is applied internally, and as the tube expands outward between the plates, it is folded longitudinally to produce a complete, convoluted bellows in one operation. This fabrication method produces excellent quality bellows at the lowest possible cost for high volume production.

Design Details

Extra flexible bellows have an increased convolution depth for greater travel and lighter spring rates. To achieve this, the root diameter is less than the tube diameter. We call these “beaded” bellows. Beaded bellows can be formed using seamless drawn tubing.

Mechanically roll-formed bellows begin with the thin-walled tube, shallow convolutions are successively formed along the tube’s length. These are deepened and narrowed through additional rolling operations until the final diameters and lengths are achieved. This process is used more for larger bellow sizes as well as smaller multi-ply bellows that require roll-forming due to the total tube thickness involved.

Design Details

Multiple-ply bellows are often used in applications demanding a higher-pressure factor without excessive loss of flexibility. They are made by laminating two or more close-fitting tubes, then forming the convolutions as done with single-ply bellows. Two-ply, three-ply and four-ply bellows are offered in various materials for specialized applications. Roll-formed bellows can be made with either seamless drawn or seam-welded tubes.

Certified Processes

Fulton Bellows is vertically integrated, allowing greater flexibility in the manufacturing of bellows and bellows assemblies. From our master coils, we have the flexibility for custom seamless tube sizes. Our in-house machine shop allows us to develop and maintain all of our tooling. We have various annealing and heat-treating capabilities that permit us to process many different types of materials. We have the capability to form bellows by hydroforming or mechanically forming depending on the application. Finally, our processes allow us to form many different end and bottom configurations.