Semiconductor

Fulton Bellows works with numerous semiconductor applications, providing cutting-edge bellows that are essential for critical processes. Our meticulously designed and expertly crafted bellows play a pivotal role in semiconductor manufacturing, offering unrivaled performance and reliability in the most demanding circumstances.

When it comes to pressure regulation, actuation, and flow monitoring, Fulton Bellows products can be trusted for reliable and robust performance, even in the most challenging operating conditions.

Our bellows are indispensable in protecting expensive batch processes from over-temperatures or pressures. With utmost precision, they make critical decisions in safety processes, ensuring the well-being of your valuable equipment and personnel. Furthermore, our bellows optimize chemical reactions by seamlessly opening and closing fluid regulation systems, regardless of the chemical being processed or the pressures surrounding them.

At Fulton Bellows, we understand the diverse needs of the semiconductor industry. Our bellows are designed to adapt to various applications and chemical environments. Whether it’s controlling gases, managing pressure differentials, or maintaining tight seals, our bellows provide the reliability and flexibility needed to optimize semiconductor manufacturing.

With a proven track record and an unwavering commitment to excellence, Fulton Bellows is the trusted partner for semiconductor manufacturers worldwide. Our dedication to precision engineering and superior performance has earned us the trust of industry leaders.

Basic and Common Applications

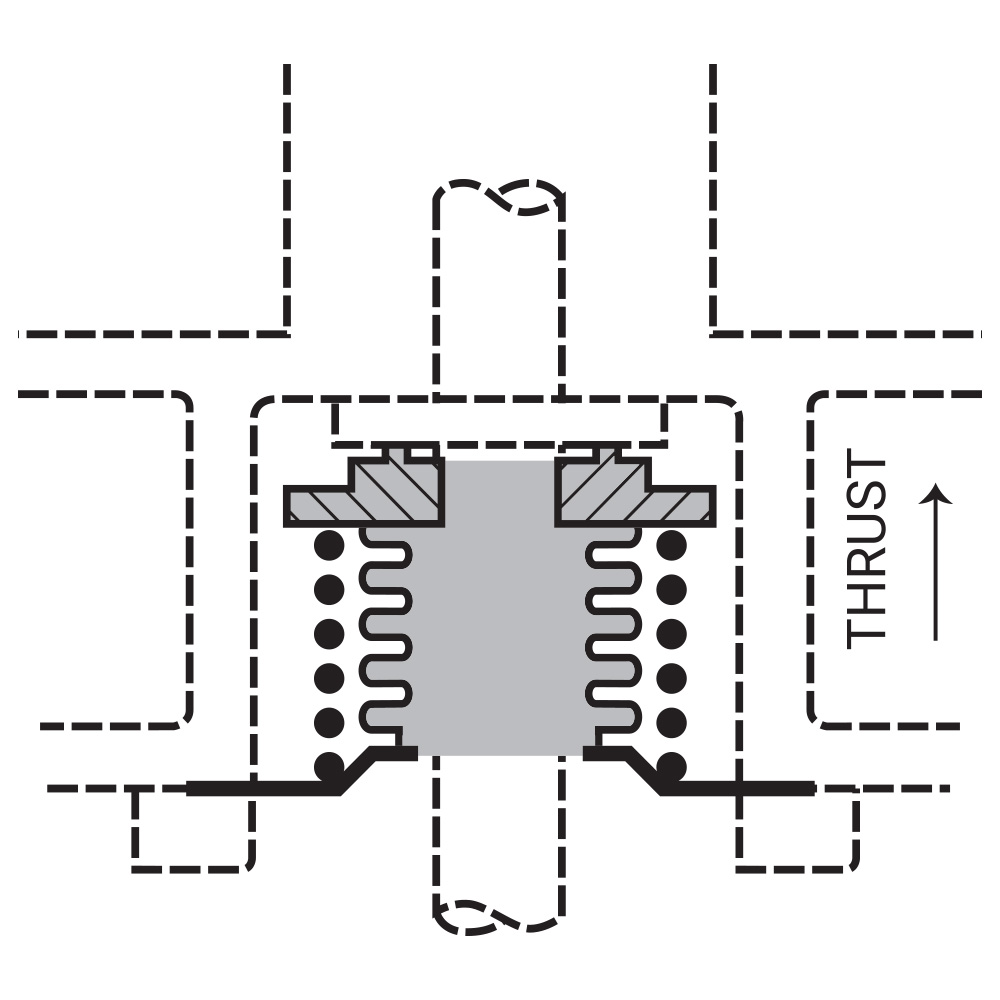

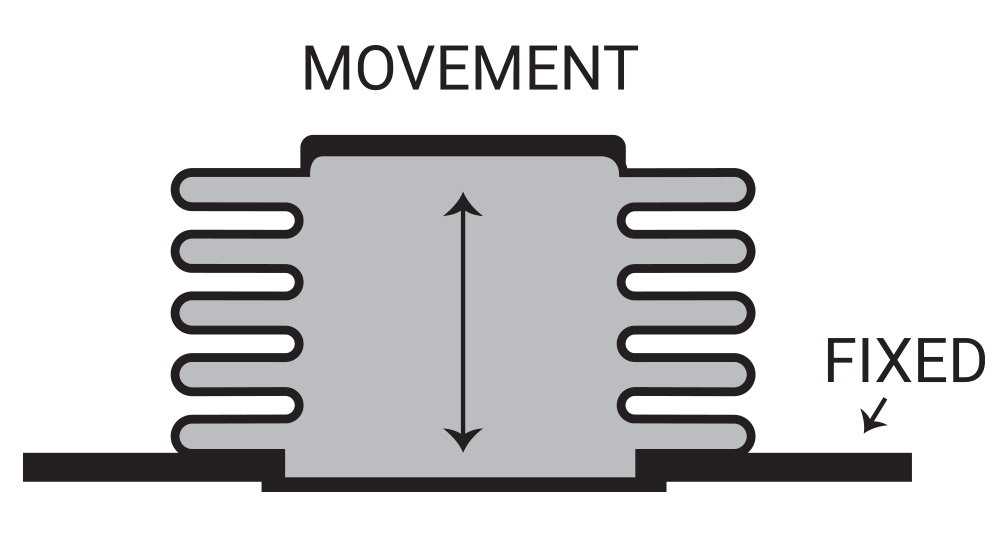

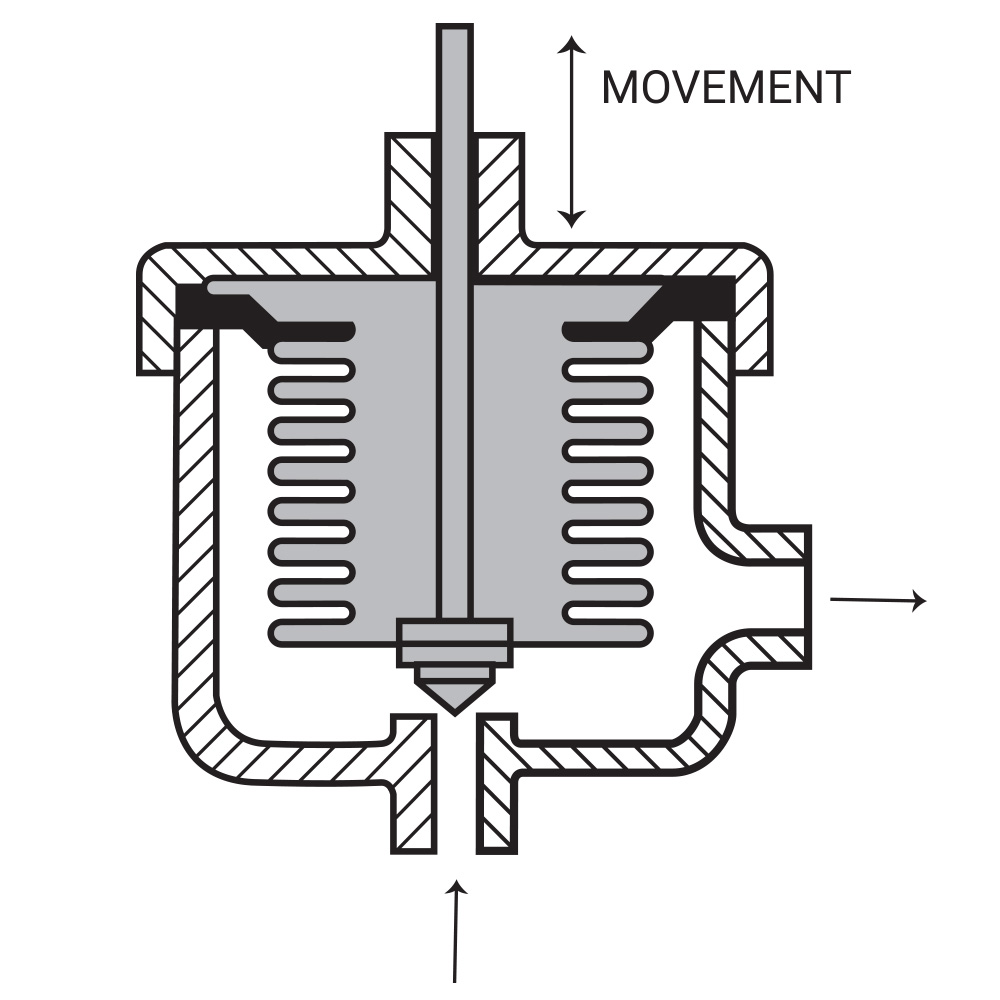

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

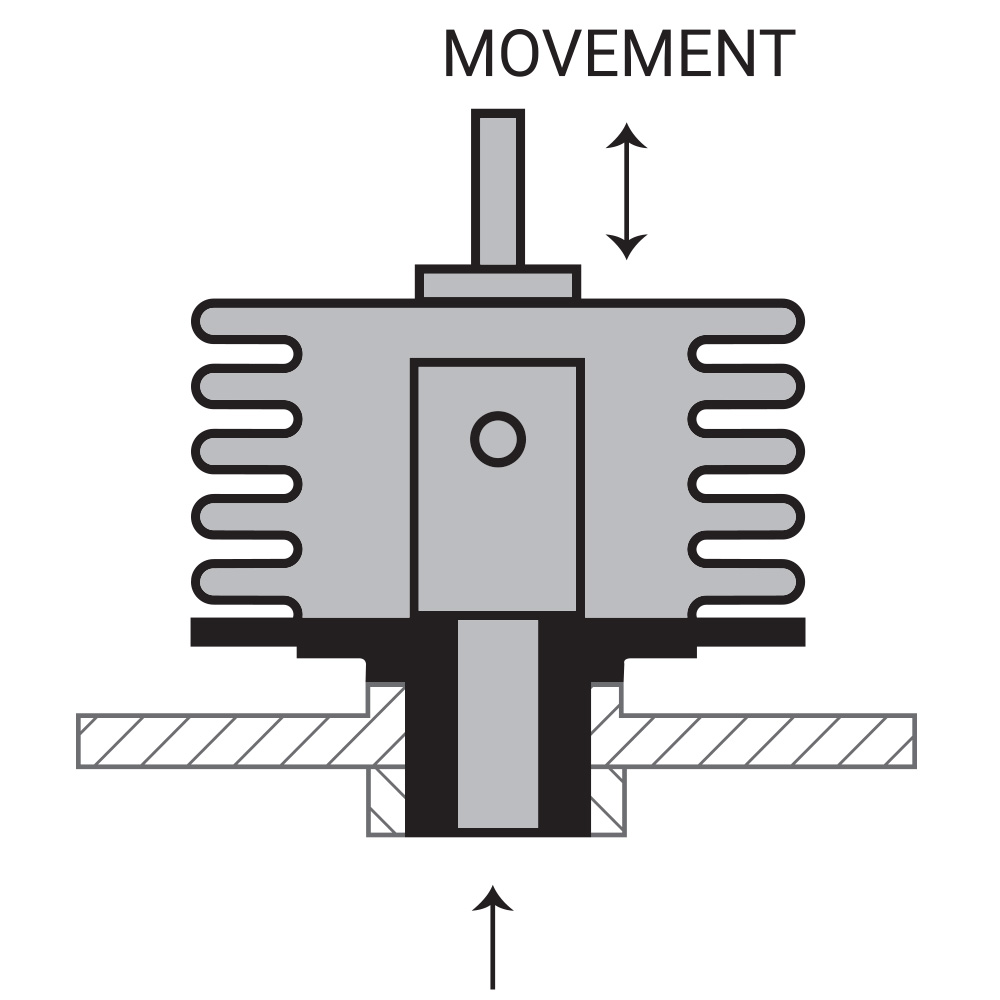

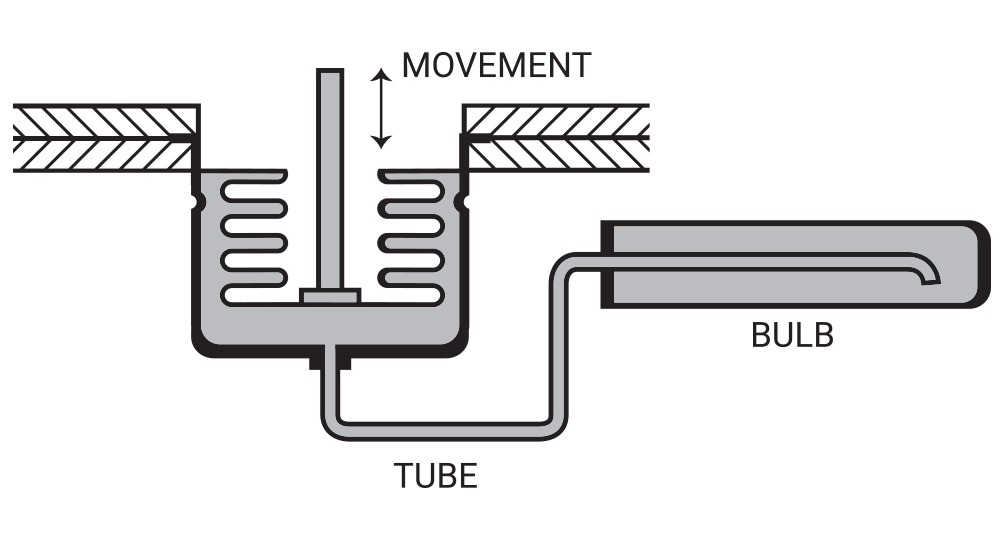

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.