Power Generation

Fulton Bellows stands at the forefront of the power generation industry, revolutionizing it through innovative bellows technology. In power generation, accurate control of pressure, temperature, and fluid flow is paramount. Fulton Bellows offers a comprehensive range of regulators designed specifically for power generation applications. Our pressure regulators ensure stable and reliable pressure control within various power generation systems, optimizing efficiency and ensuring operational safety.

Additionally, our temperature regulators enable precise temperature management, safeguarding equipment and enhancing overall performance. Meanwhile, our flow regulators facilitate the controlled flow of fluids, maintaining optimal operating conditions and maximizing energy generation.

Our products find wide-ranging applications, particularly in the plumbing and boiler segments, where water and steam are integral to the power generation process. Our bellows technology ensures seamless operation and efficient heat transfer within these systems. The flexibility and durability of our bellows enable precise control over fluid flow, pressure, and temperature, promoting optimal performance in power generation applications.

Within diesel and natural gas-fired ground turbines, Fulton Bellows’ high-pressure bellows applications are deployed in fuel staging valves. These valves play a critical role in managing the combustion process by controlling the fuel flow and distribution within the turbine. Our bellows technology provides the necessary resilience to withstand high pressures, ensuring precise fuel delivery and efficient turbine performance.

Basic and Common Applications

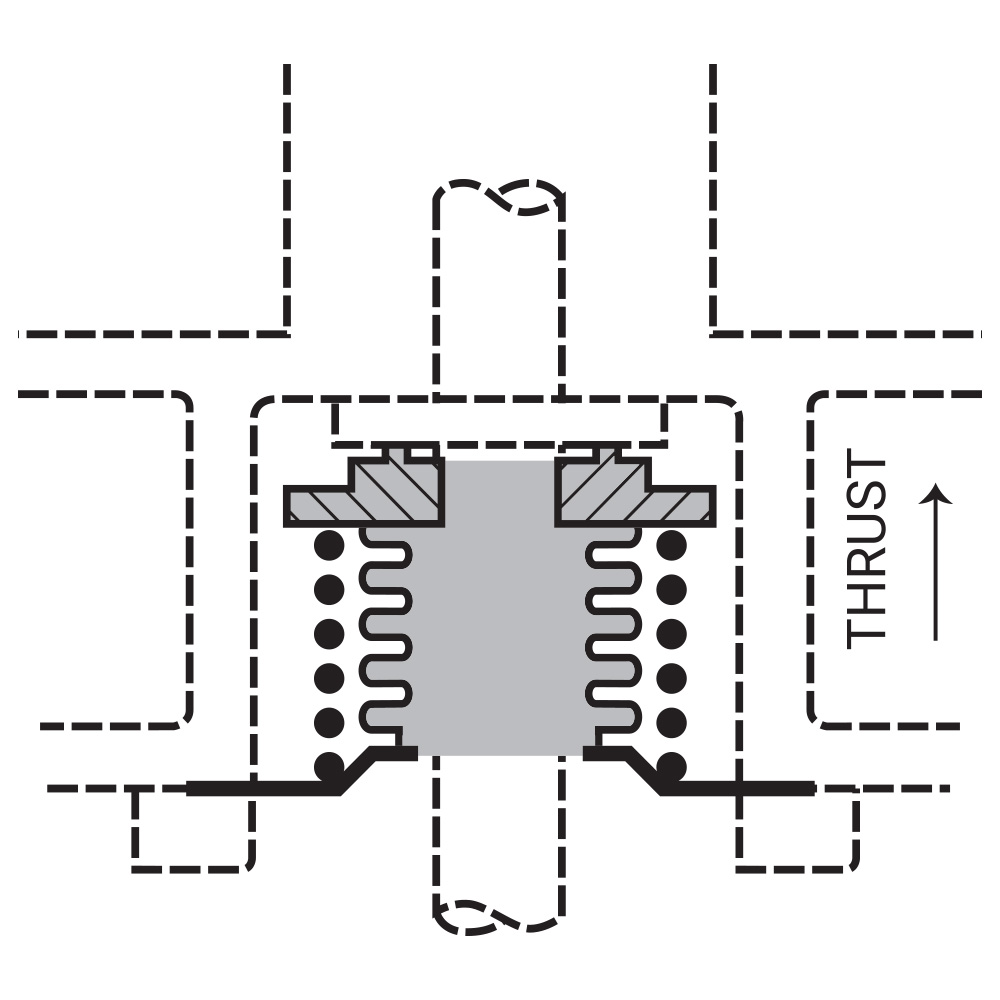

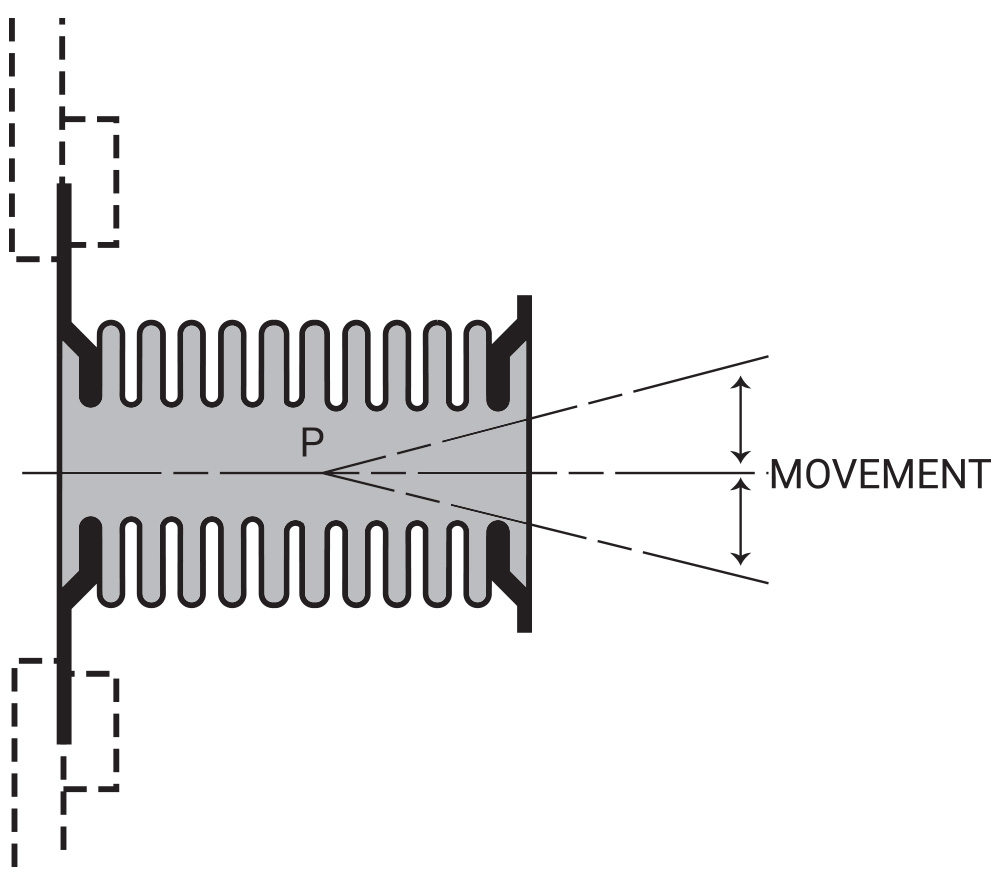

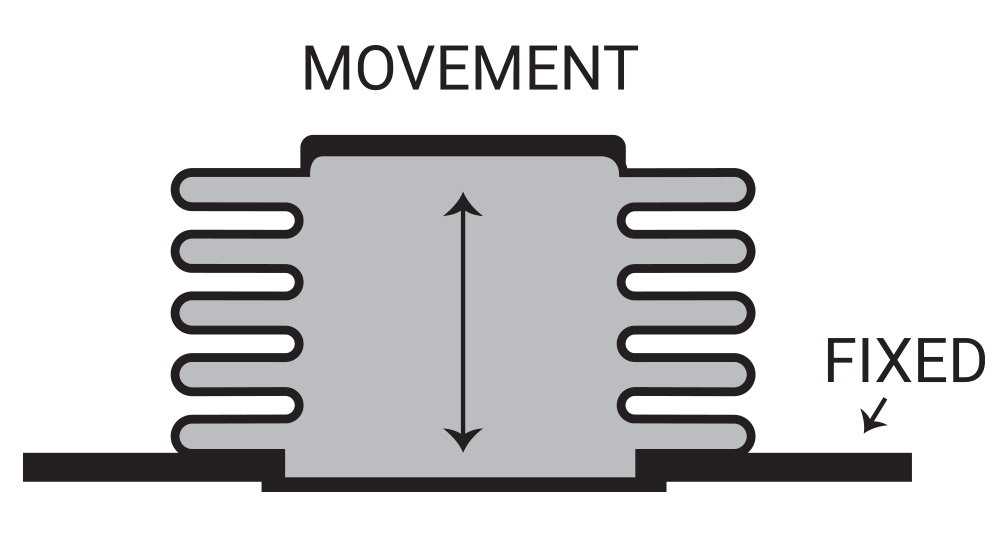

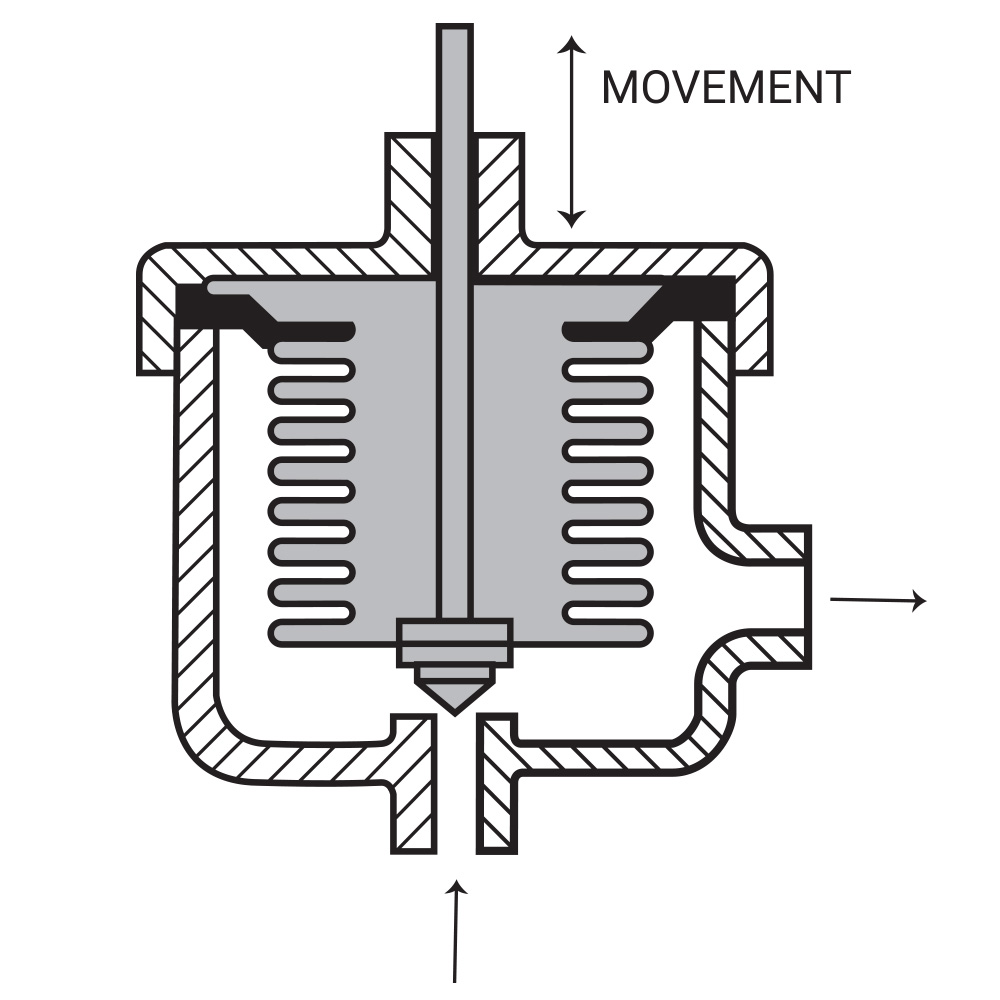

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

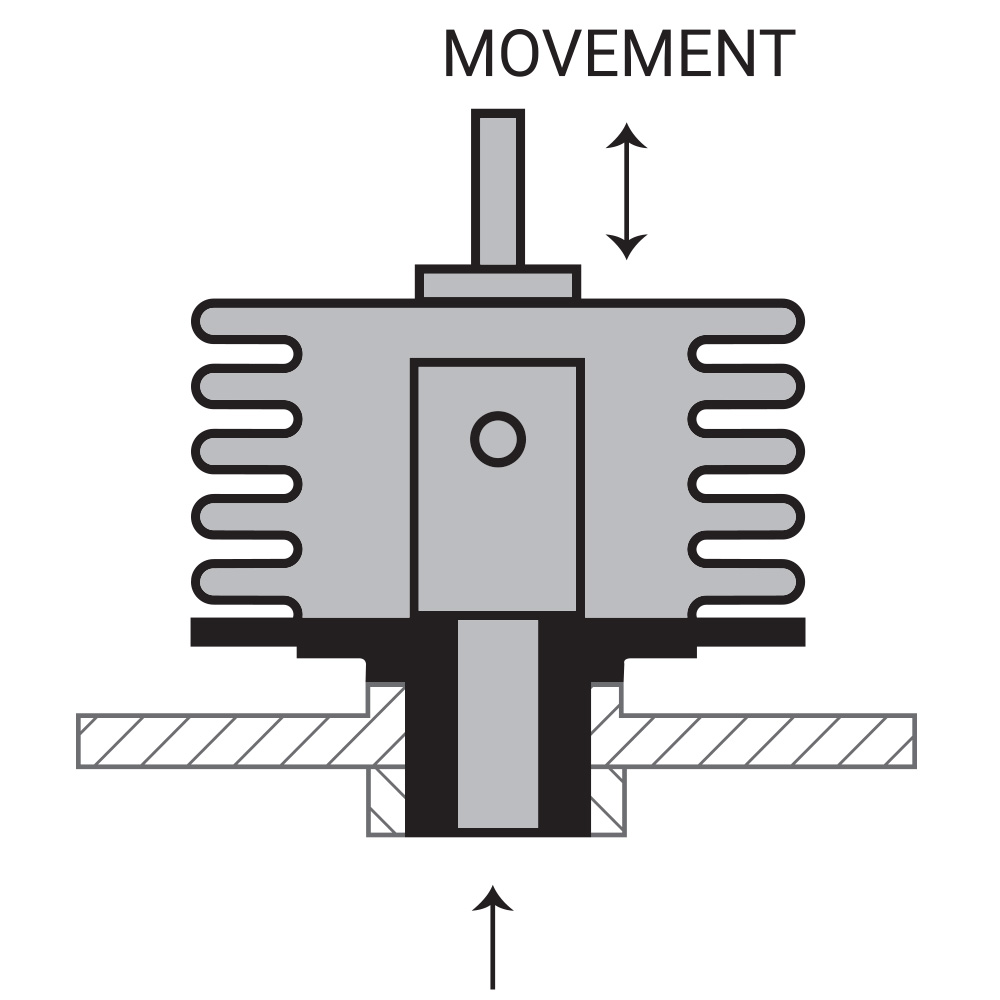

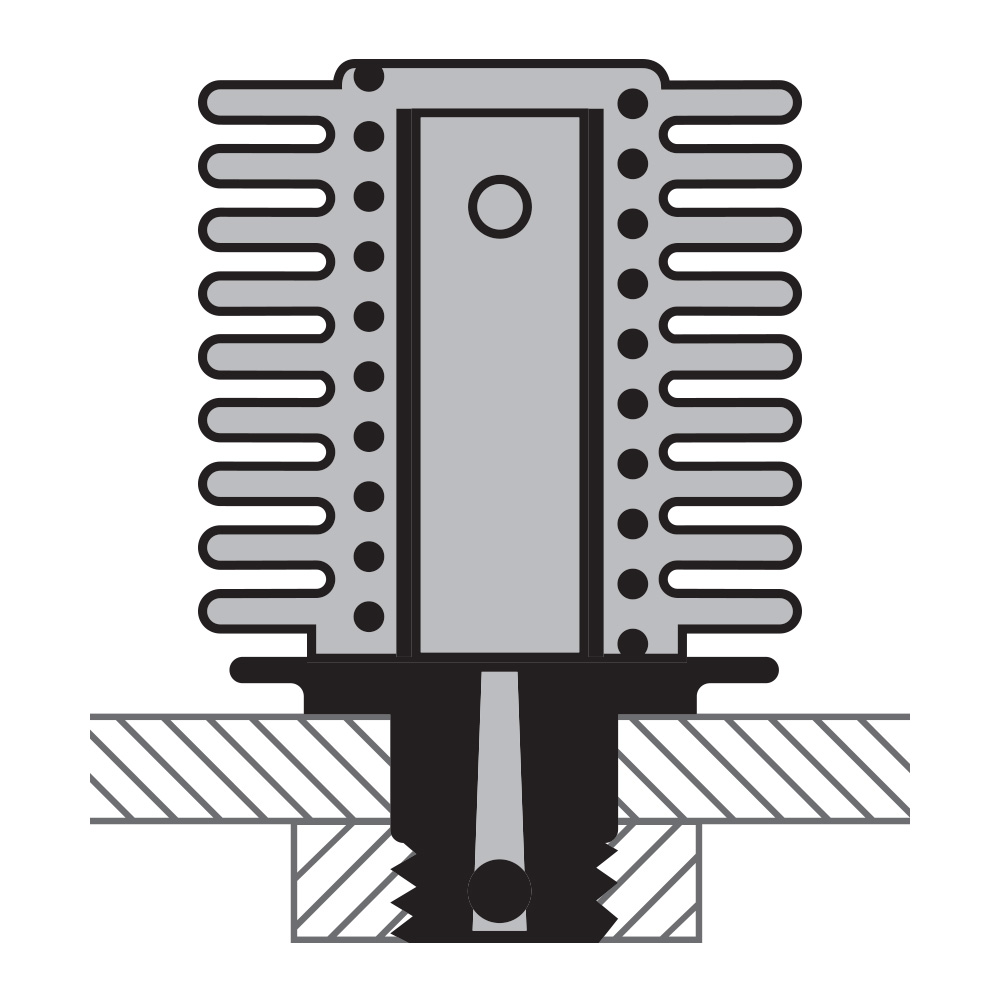

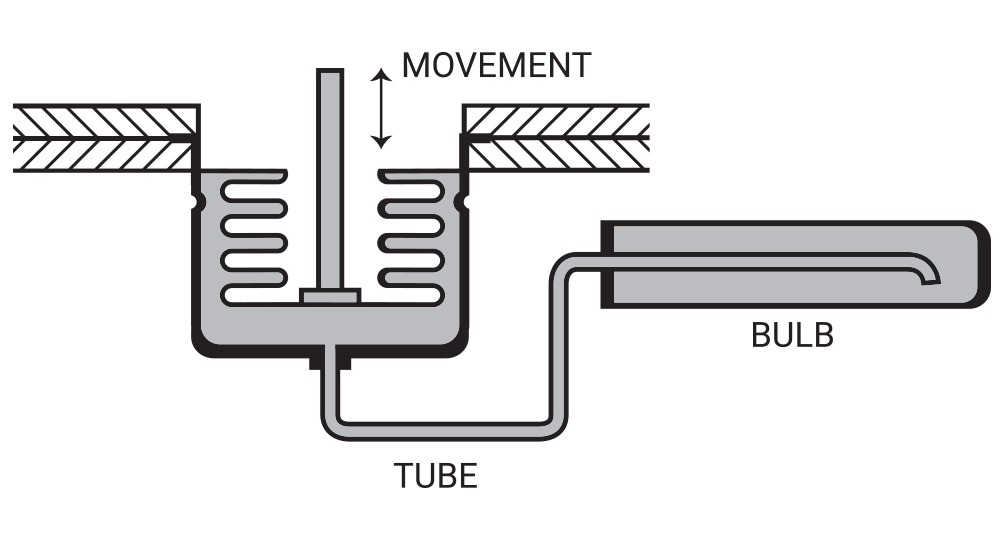

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.