Oil & Gas

Fulton Bellows plays a vital role in the oil and gas industry by providing bellows and bellows assemblies for downhole instrumentation and oil pumping applications. Our robust and flexible bellows ensure reliable performance in challenging downhole environments. They facilitate precise measurement and control of fluid levels, pressures, and temperatures, enabling efficient oil extraction and well monitoring.

In addition to downhole applications, our bellows technology is utilized in above ground valves and regulators. These devices are essential for the safe and efficient transportation and processing of various fluids. Fulton’s wide variety of material choices proves invaluable in situations where aggressive fluids are encountered. Our carefully selected materials ensure longevity and reliability, even in the presence of corrosive substances.

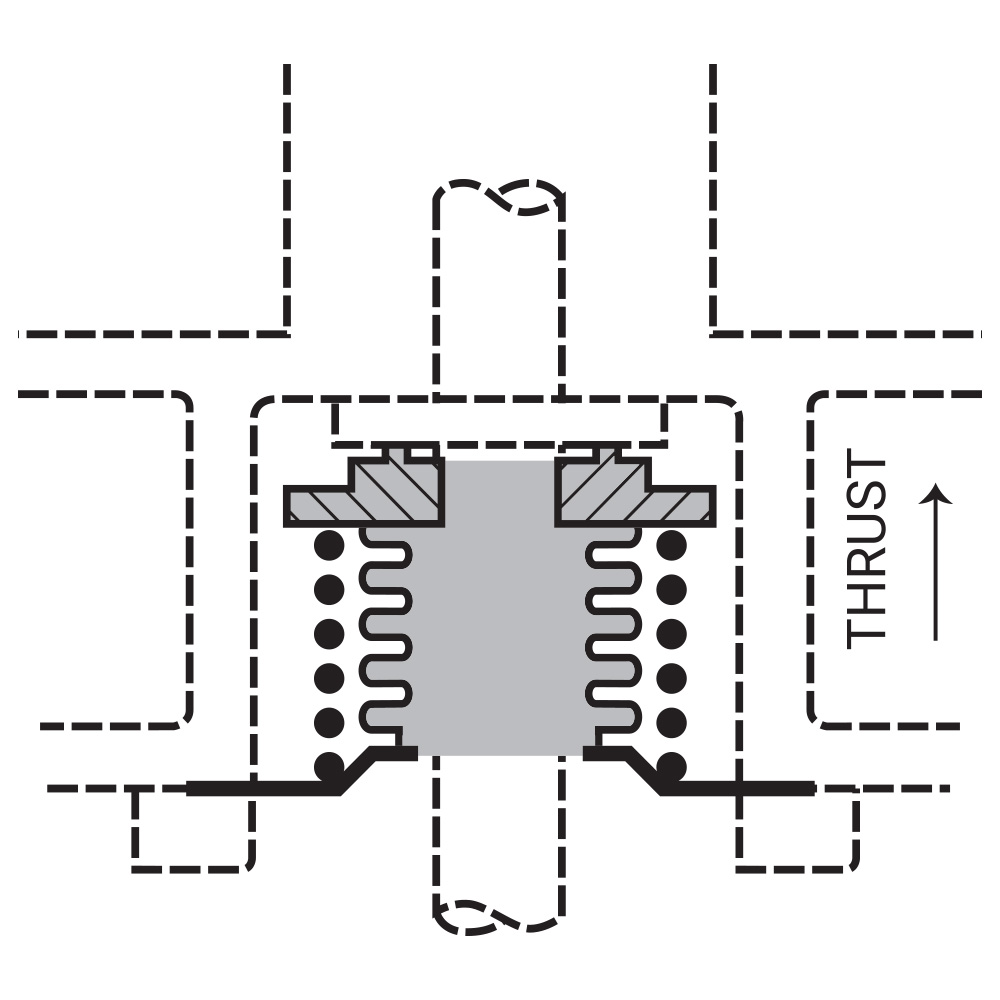

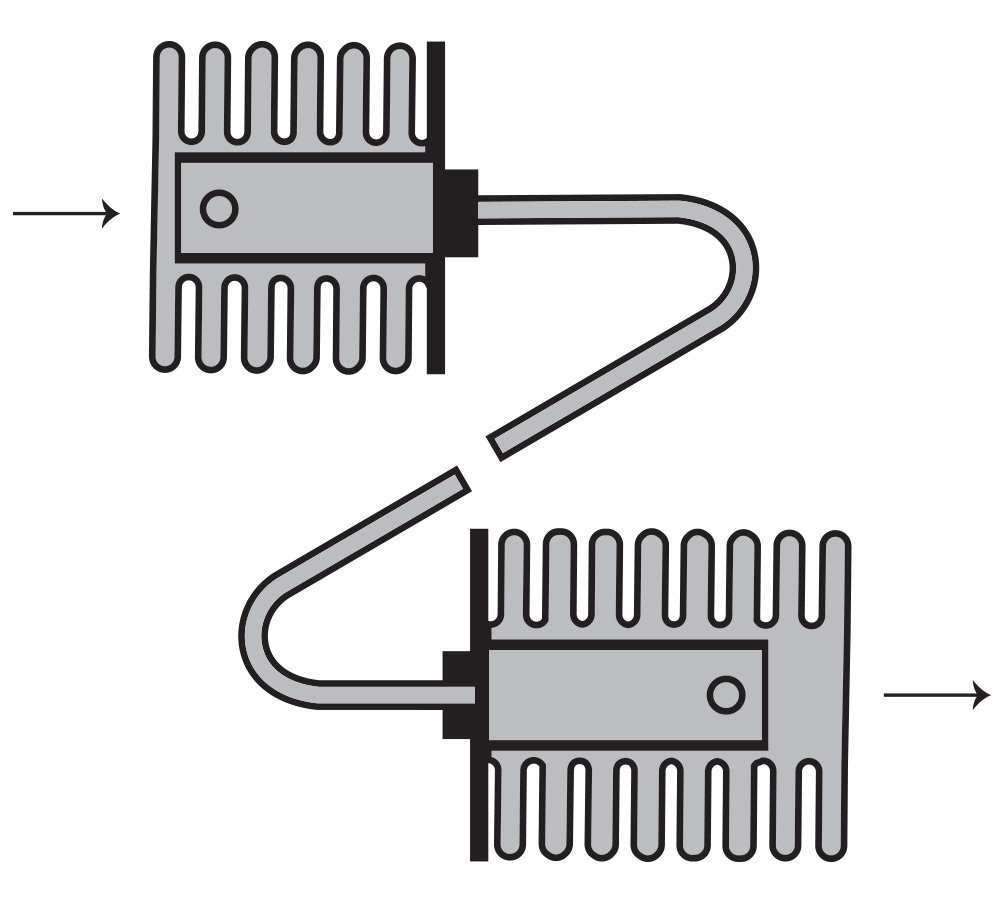

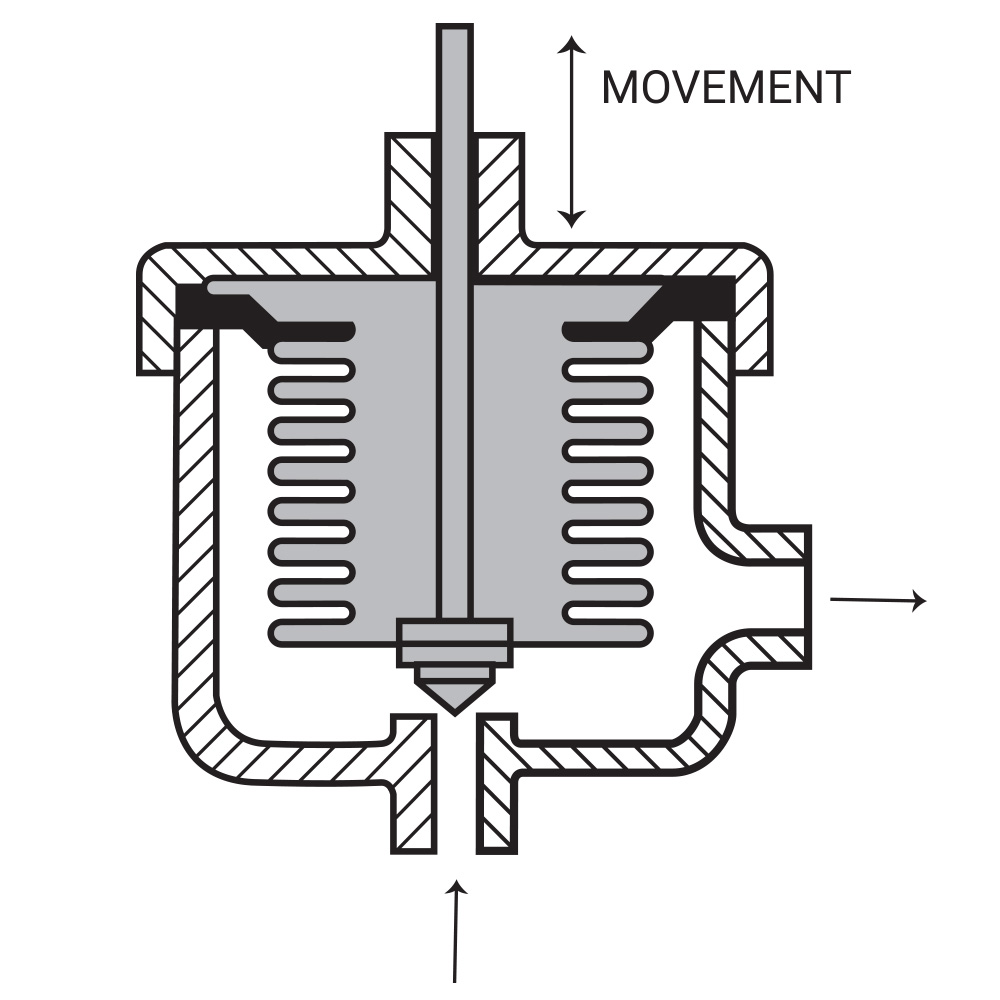

Fulton’s bellows are also critical components in “gas-lift” valves, which are used for artificial-lift equipment in the oil and gas industry. These valves enhance the production of oil wells by injecting gas to lift the oil to the surface. Our bellows provide the necessary flexibility and durability required for smooth valve operation, ensuring optimal oil recovery. Moreover, our bellows technology finds application in pressure regulating “pilot valves.” These valves play a crucial role in maintaining precise pressure control, ensuring safe and efficient operation of various oil and gas processes.

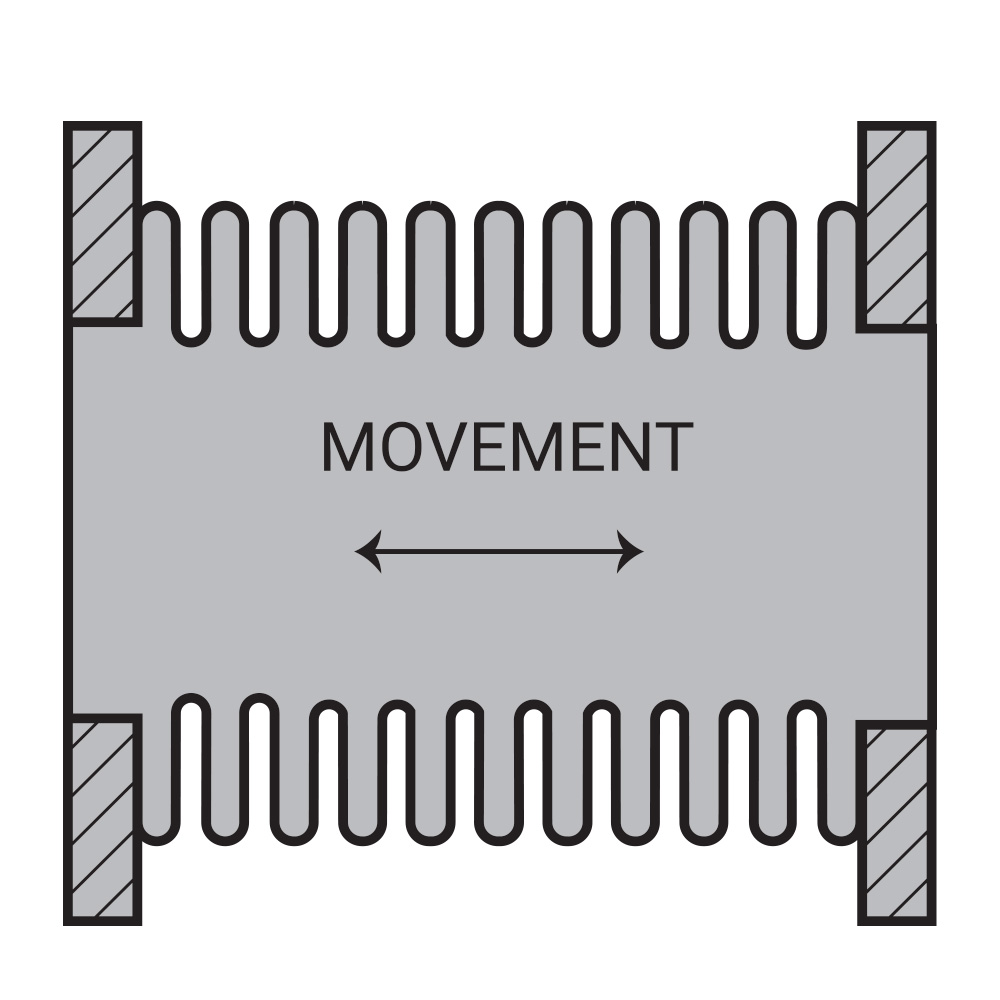

While not exclusive to the oil and gas industry, Fulton Bellows supplies bellows to customers using cryogenic devices, particularly dewar vessels. These vessels require flexible couplings that can be hermetically sealed, allowing for controlled thermal expansion and contraction. Our bellows provide the necessary flexibility and sealing capabilities, ensuring reliable and efficient performance of cryogenic equipment.

Basic and Common Applications

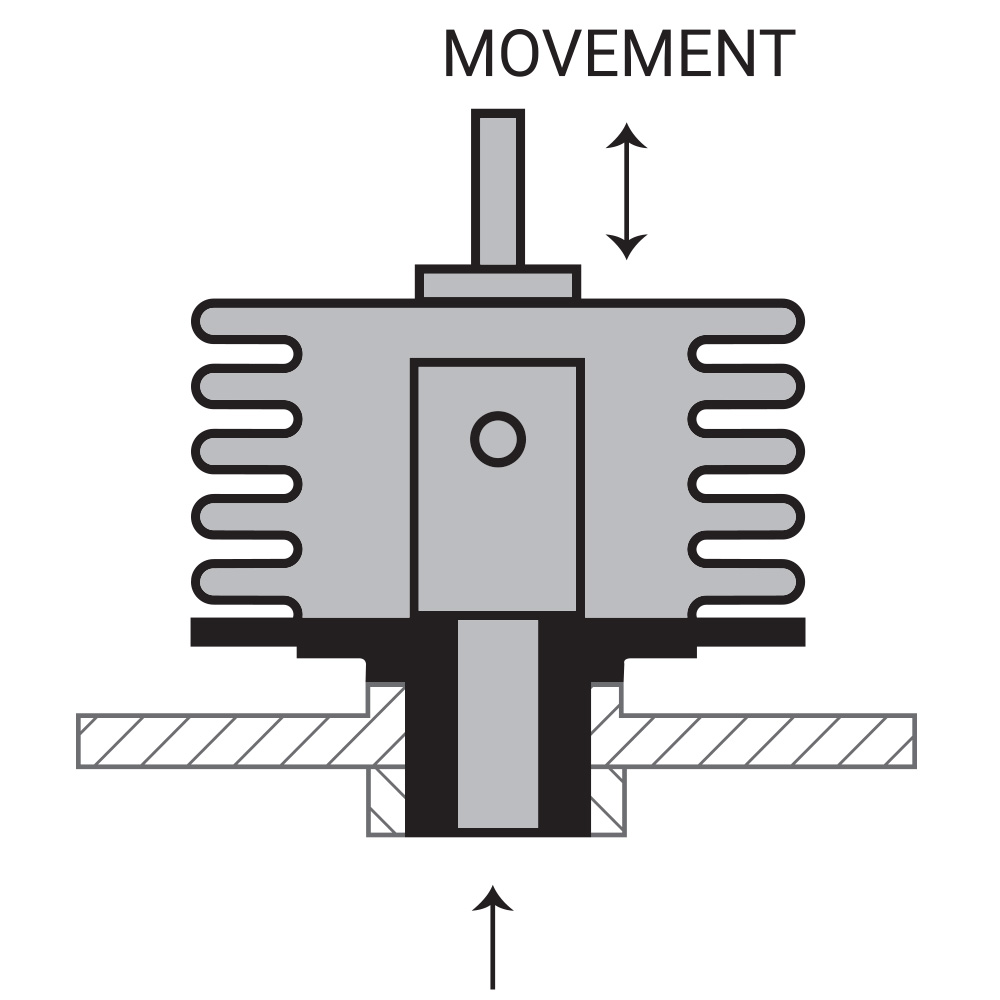

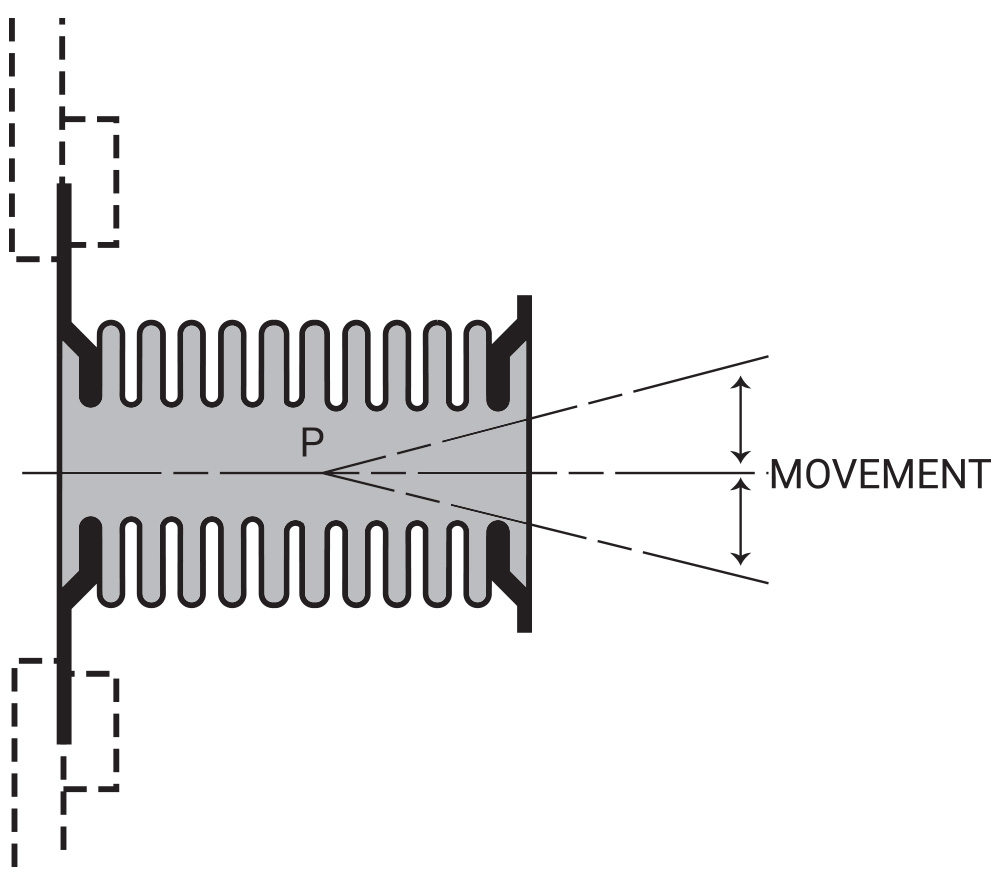

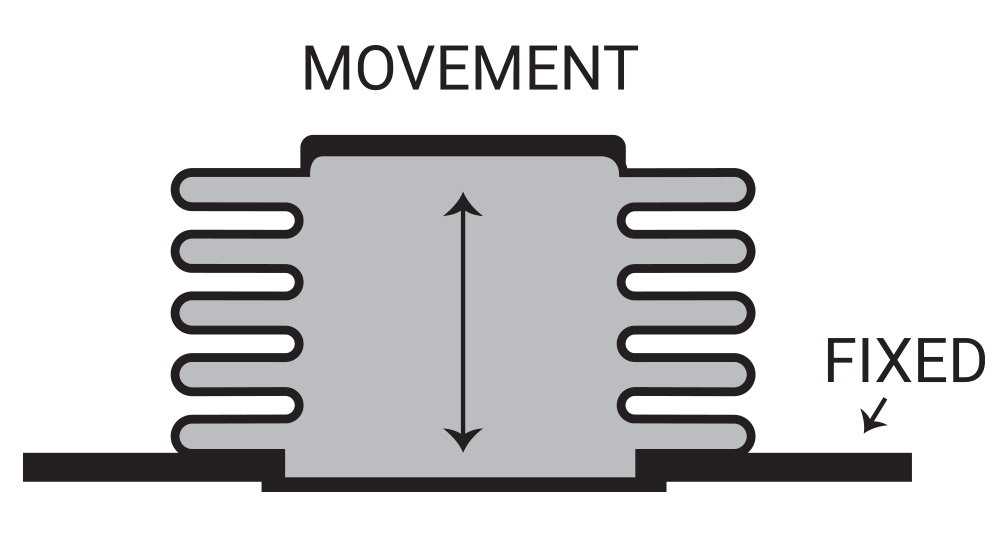

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

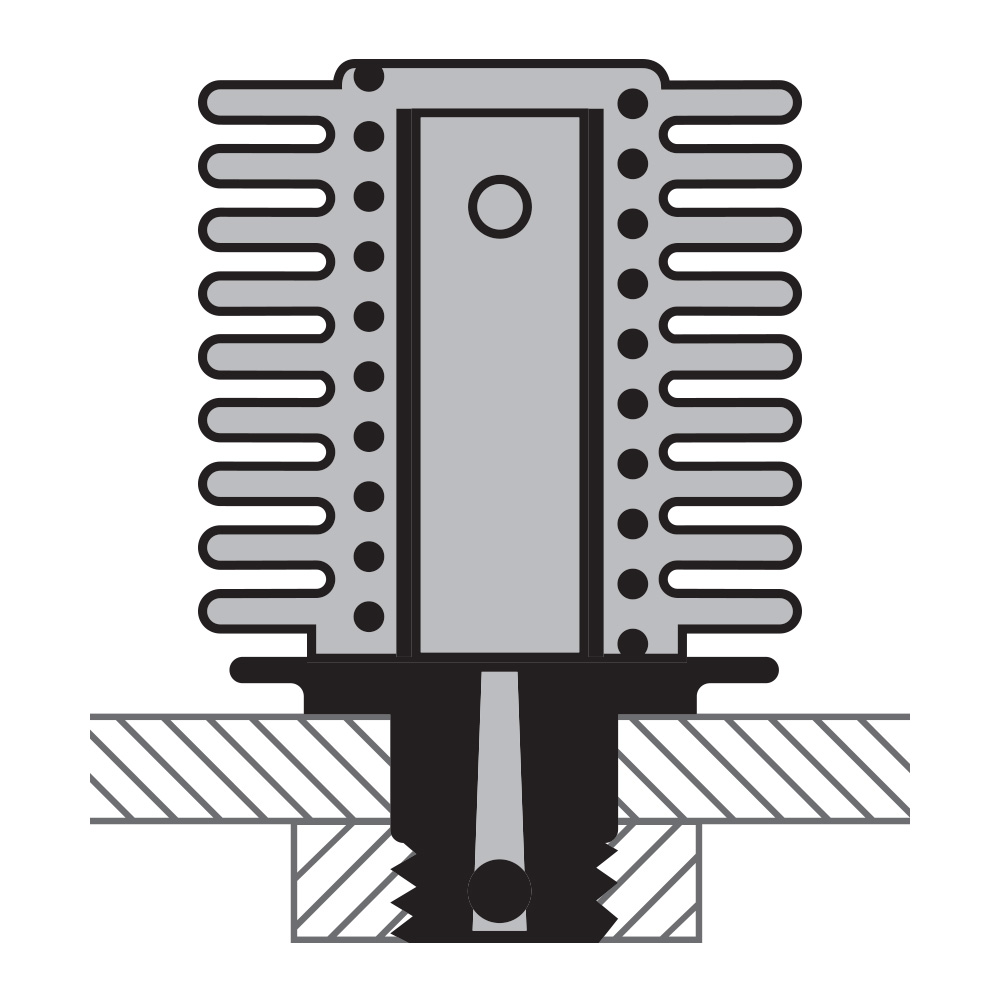

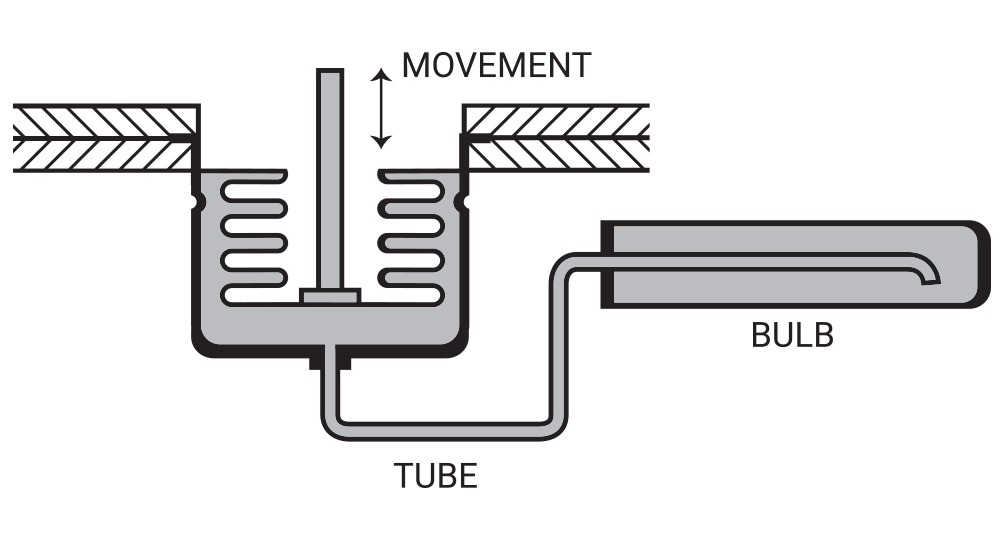

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.