Industrial

Fulton’s products are widely used in the industrial market, with applications in various industries such as plumbing, heating, ventilation, and industrial boilers. These products are designed and manufactured to meet the demanding requirements of these industries, providing reliable and efficient solutions for a broad range of applications.

In the plumbing industry, Fulton’s products are used in both household and industrial hot and cold-water plumbing controls. These products include valves, pumps, and other components that help to regulate the flow of water and ensure that it is delivered at the correct temperature and pressure. Fulton’s plumbing controls are designed to be highly reliable, efficient, and easy to use, making them ideal for a wide range of plumbing applications.

In the heating and ventilation industry, Fulton’s products are used to control the temperature and air quality in commercial and industrial buildings. These products include sensors, actuators, and control systems that work together to maintain a comfortable and healthy indoor environment. Fulton’s heating and ventilation systems are designed to be highly energy- efficient, reducing energy costs while also improving the overall comfort of building occupants.

In the industrial boiler industry, Fulton’s products are used in a variety of applications, including steam generation and control, heat recovery, and waste heat utilization. These products include boilers, burners, and control systems that are designed to be highly efficient and reliable, providing cost-effective solutions for industrial heating applications.

Overall, Fulton’s products have a wide variety of uses within the industrial market, providing reliable and efficient solutions for a broad range of applications. With a focus on quality, innovation, and customer service, Fulton continues to be a leading provider of advanced engineering and manufacturing solutions for the industrial market.

Basic and Common Applications

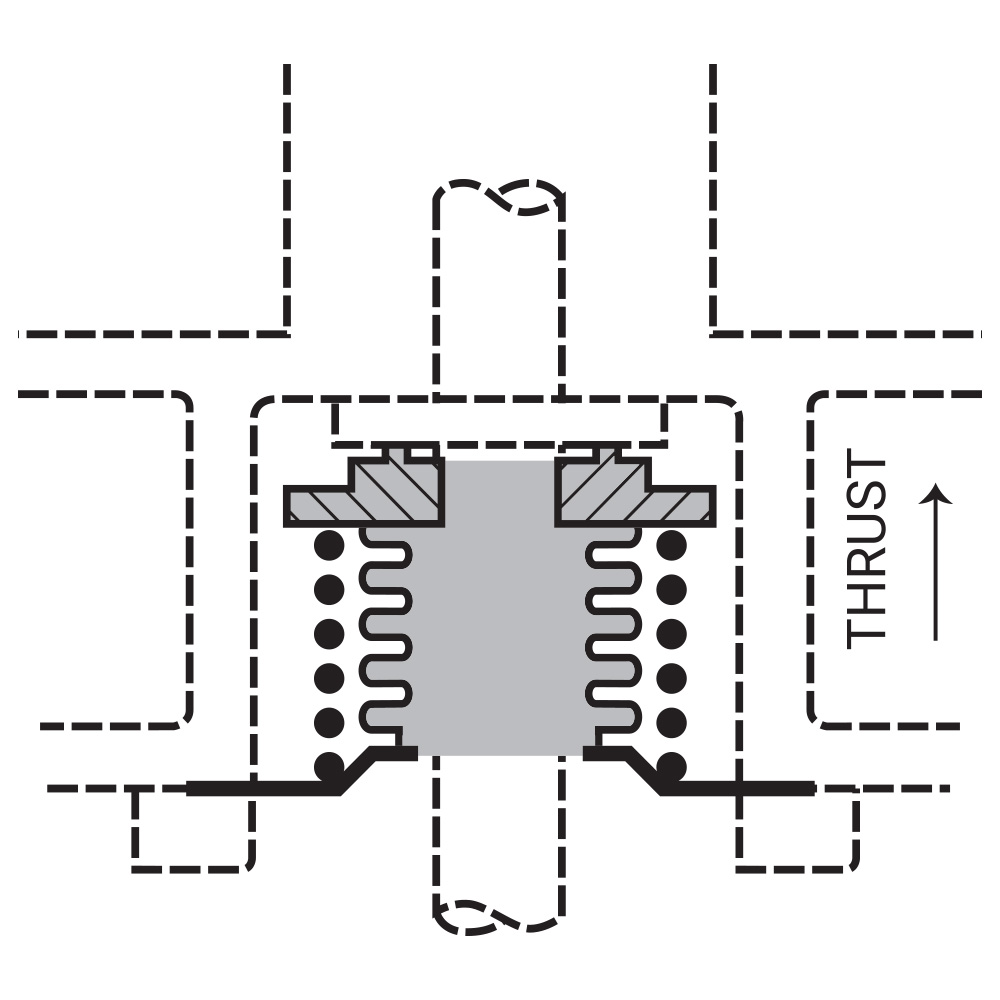

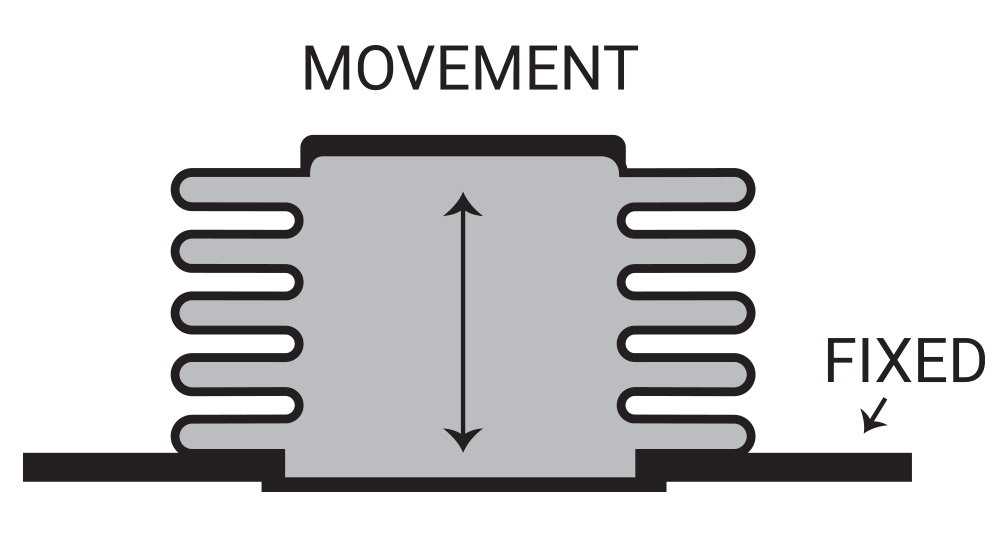

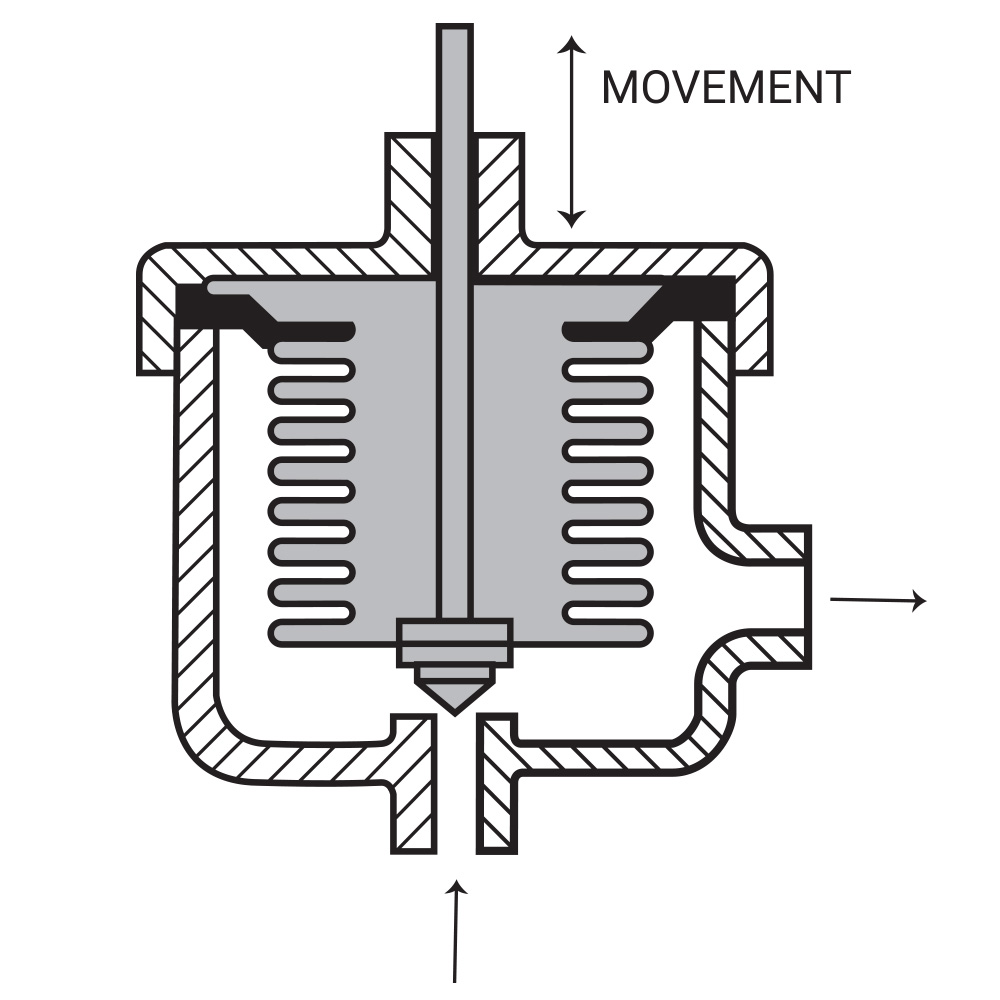

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

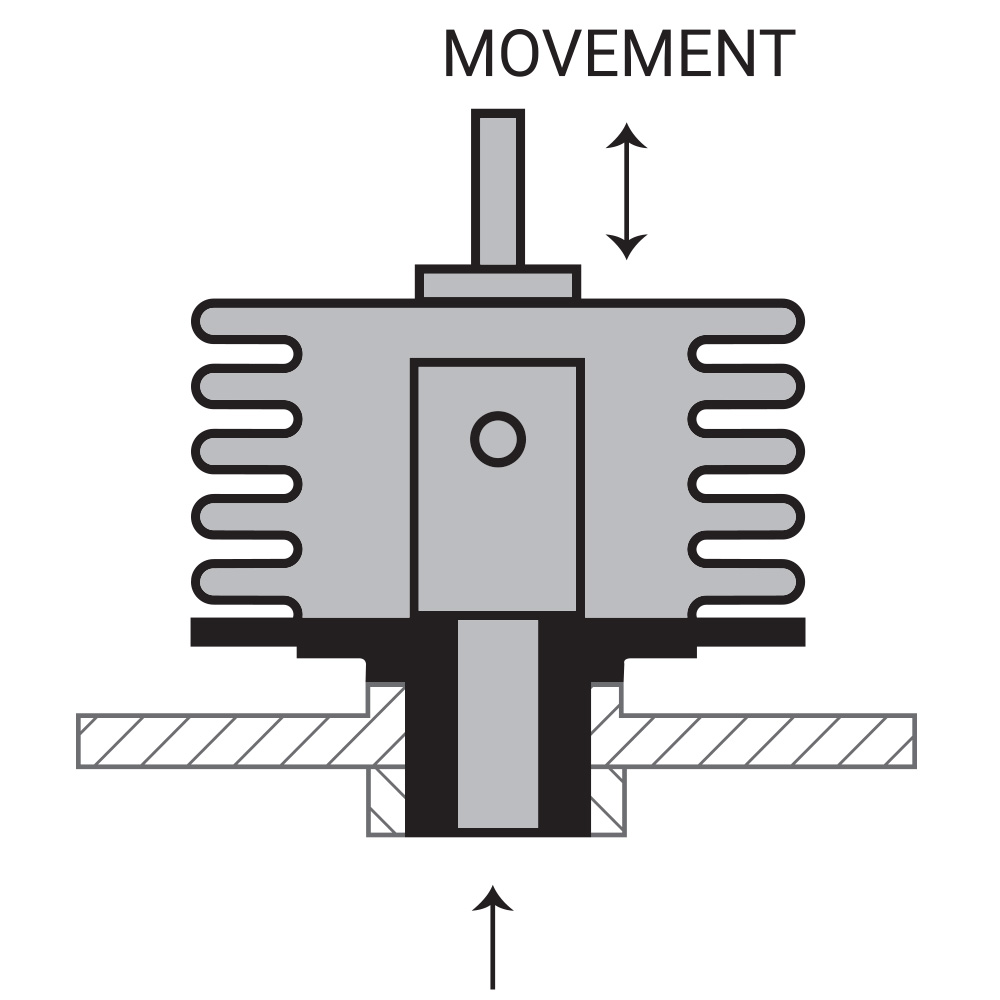

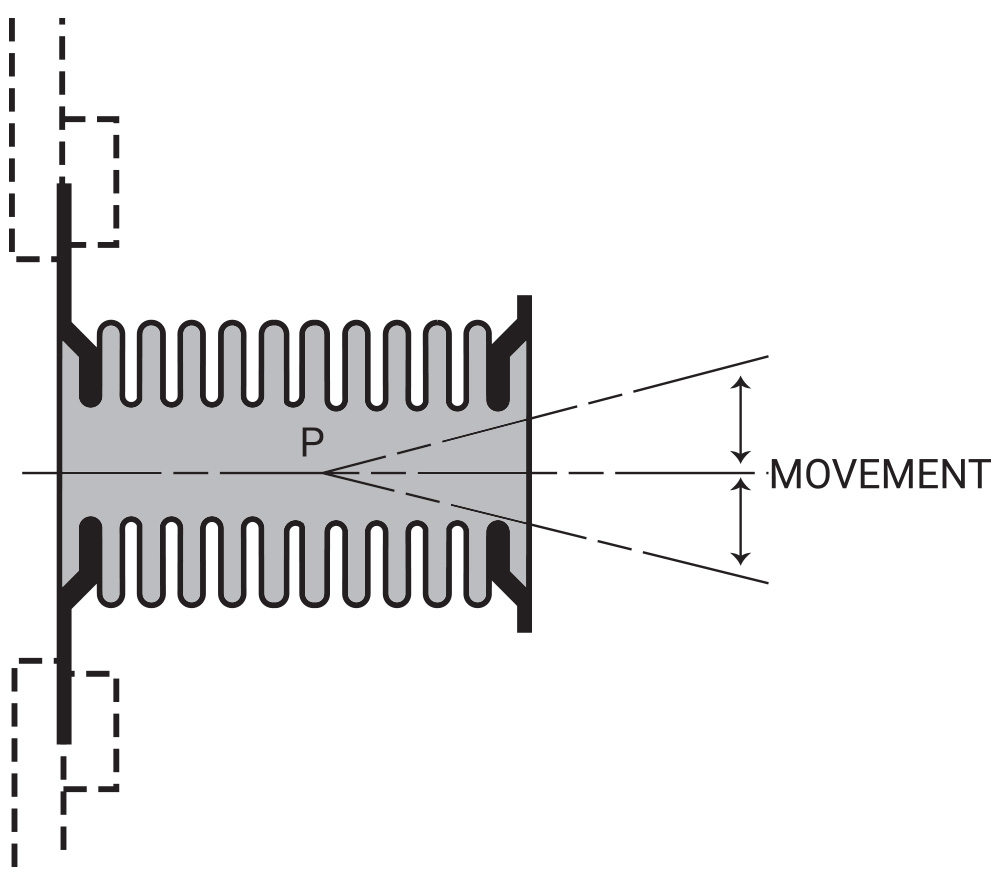

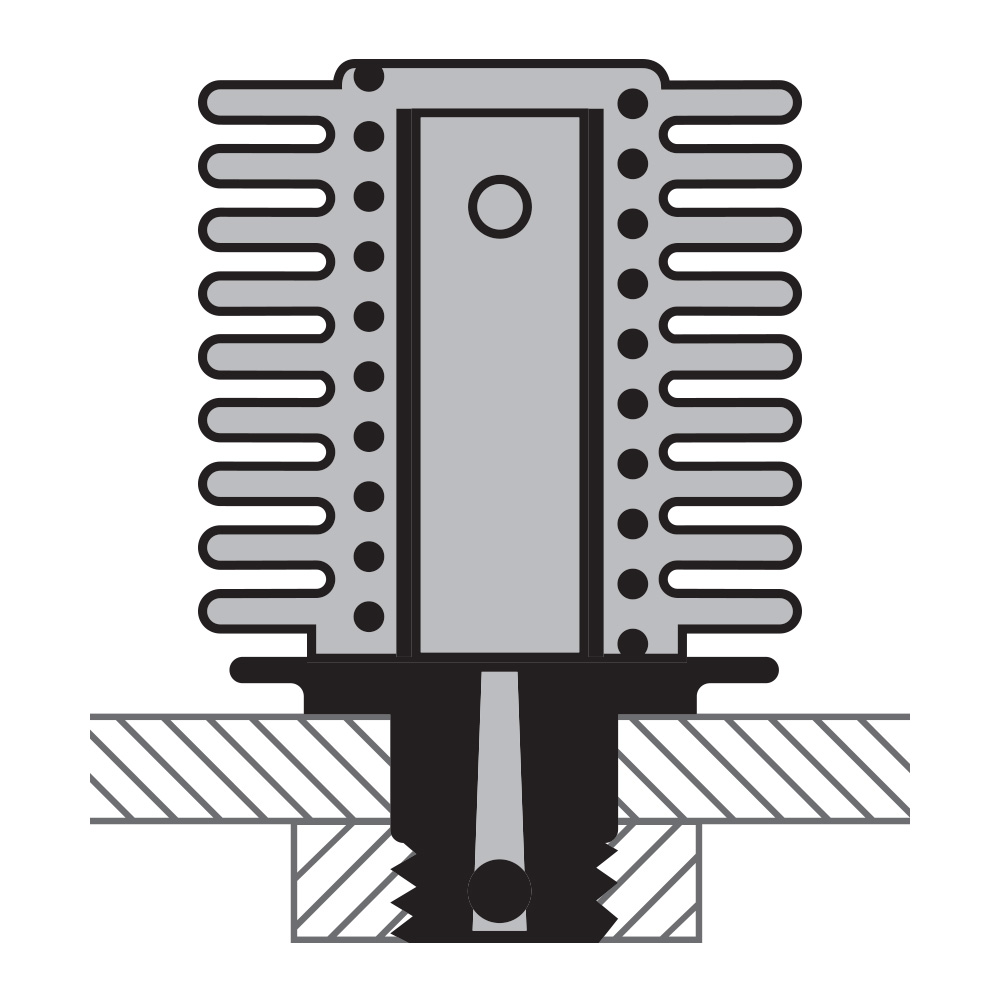

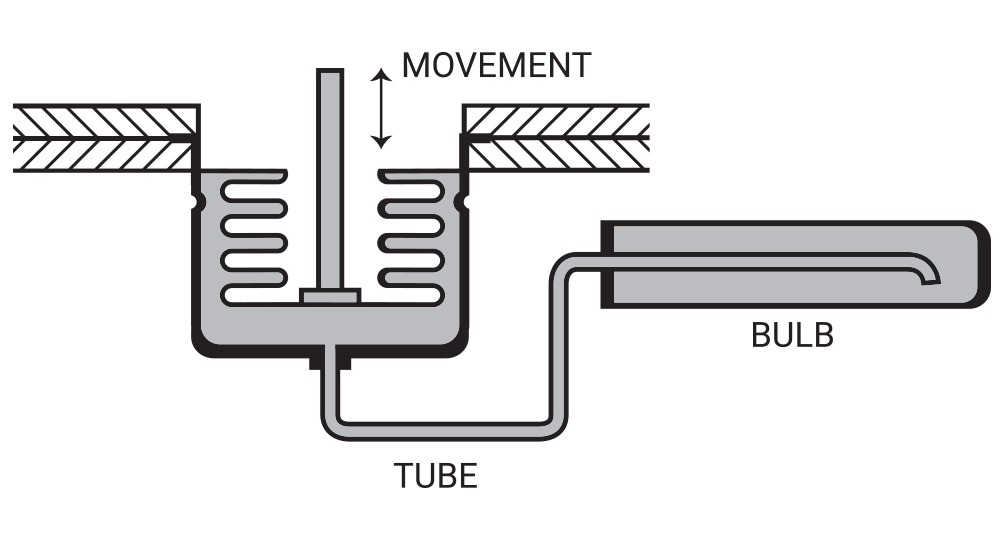

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.