Electrical Distribution

At Fulton Bellows, our expertise extends to the realm of electrical distribution applications, where our precision-engineered bellows play a crucial role in various high-voltage switchgear and cell tower installations.

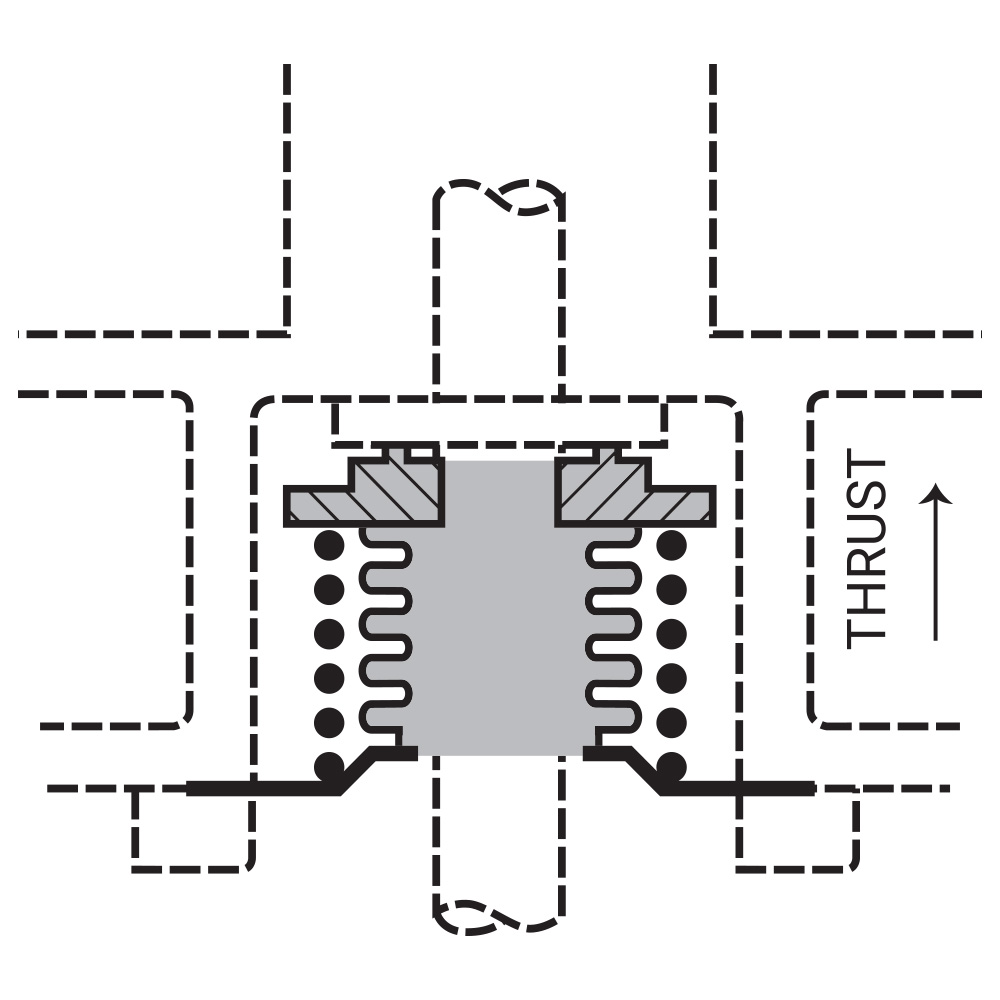

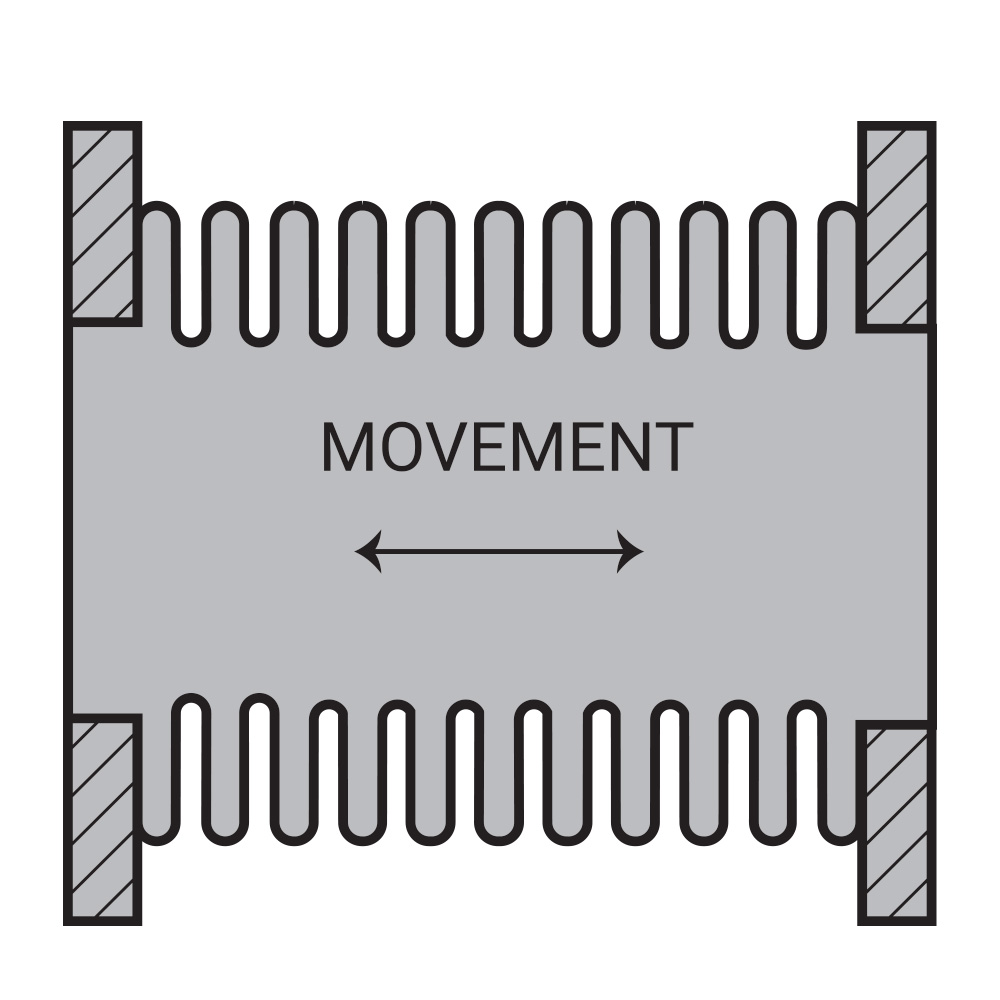

Fulton Bellows has become a trusted name in the realm of high-voltage switchgear, which includes vacuum circuit interrupters and other circuit breakers/interrupters employing SF6 atmospheres. Our bellows provide flexible coupling that can be hermetically sealed, allowing for the creation of a special environment around the electrical contacts.

In high-voltage applications, it is critical to maintain a controlled environment around the electrical contacts to ensure optimal performance and safety. Our bellows act as a flexible and reliable seal, trapping a specific atmosphere to prevent contamination or ingress of external elements. This hermetically sealed environment facilitates efficient electrical conduction, minimizes the risk of arcing, and enhances the overall reliability of the switchgear.

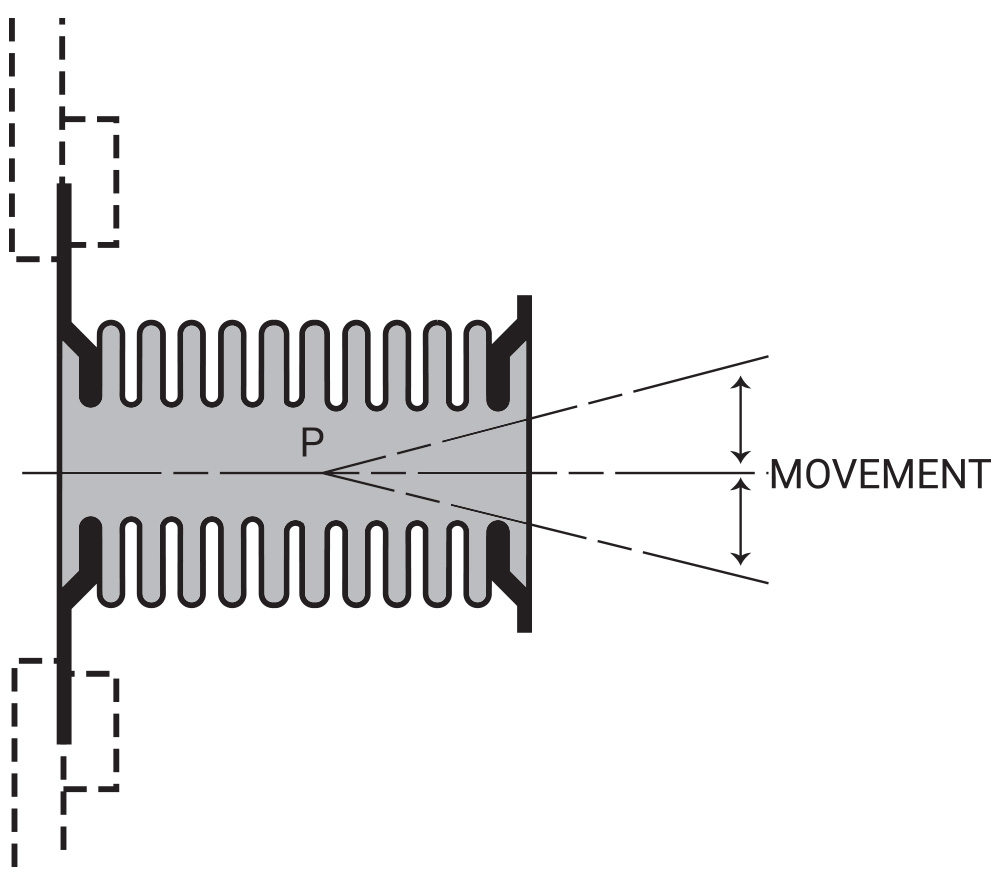

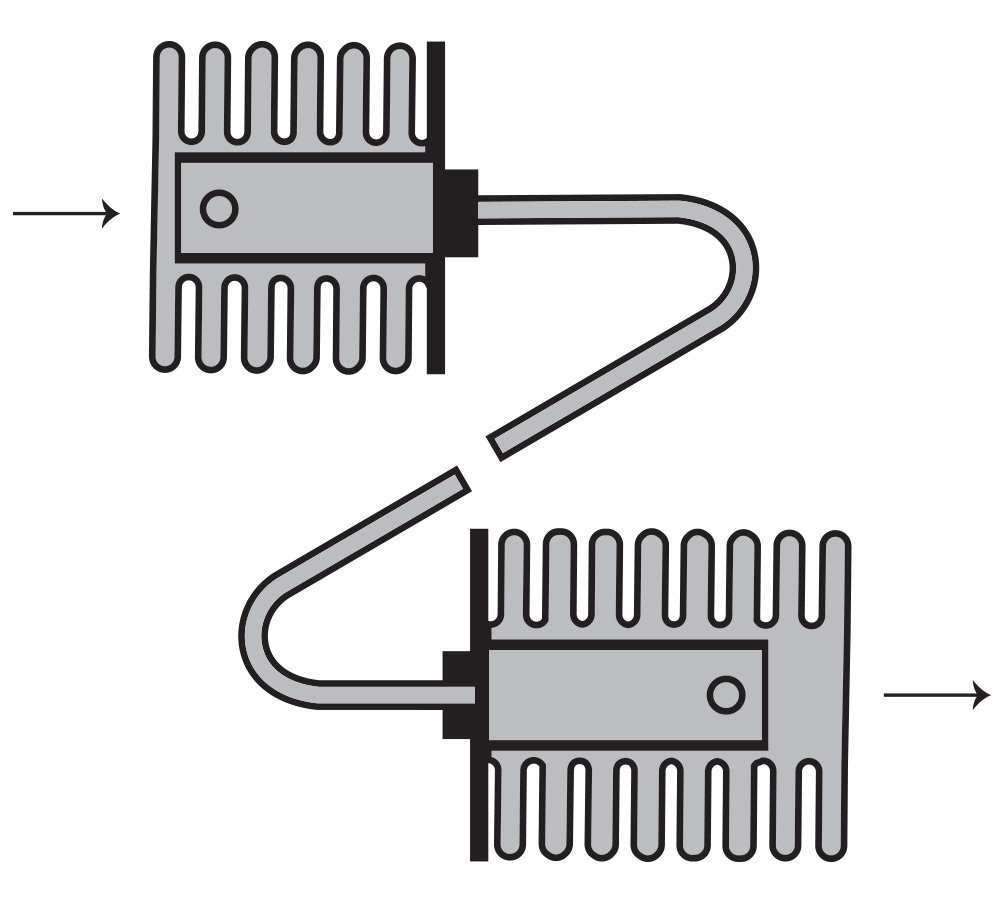

Fulton’s bellows also find extensive use in cell tower installations, where they serve as expansion couplings with unique capabilities. These bellows are designed to accommodate the expansion and contraction caused by temperature variations while providing essential electrical conductivity and supporting radio frequency (RF) wave transmission.

As cell towers are exposed to changing environmental conditions, including temperature fluctuations, it is crucial to incorporate expansion couplings that can absorb the resulting stress and movement. Our bellows excel in this role, effectively compensating for expansion and contraction while maintaining electrical conductivity.

As the demand for efficient and reliable electrical distribution systems continues to grow, Fulton Bellows remains committed to delivering high-quality solutions.

Basic and Common Applications

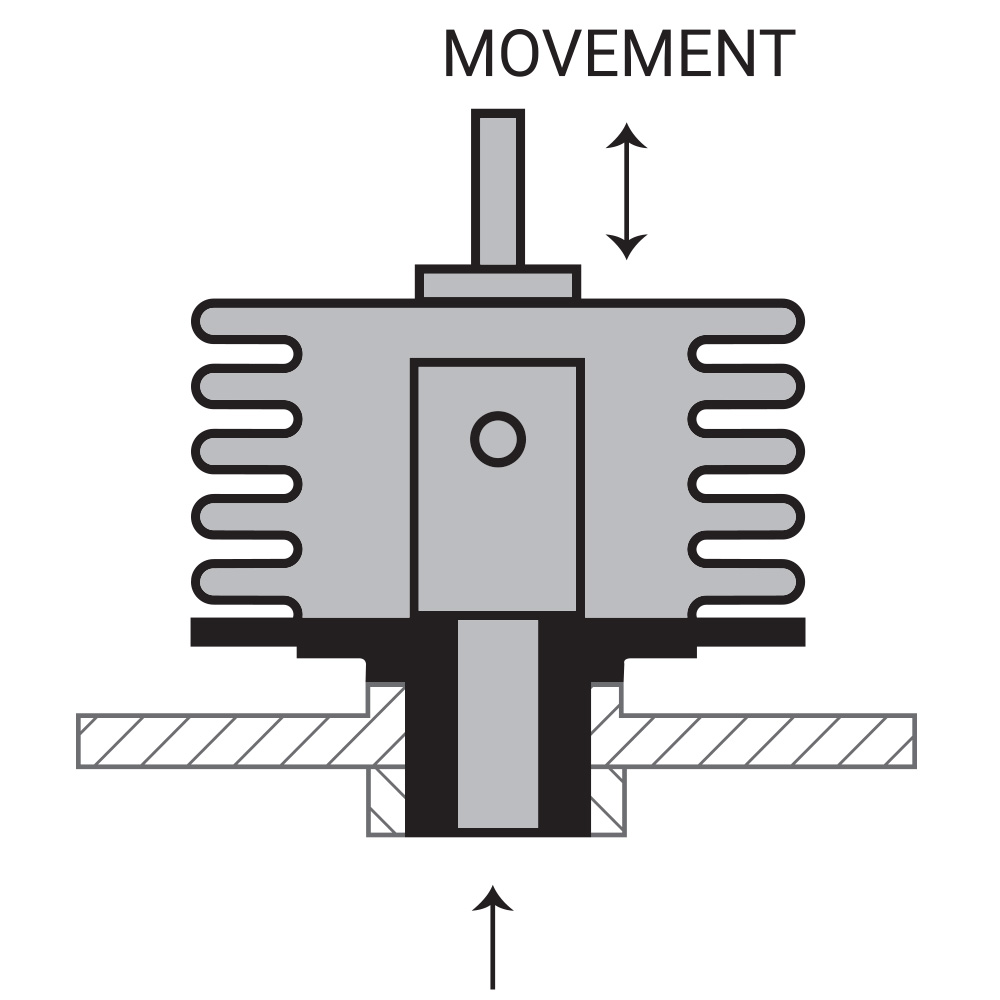

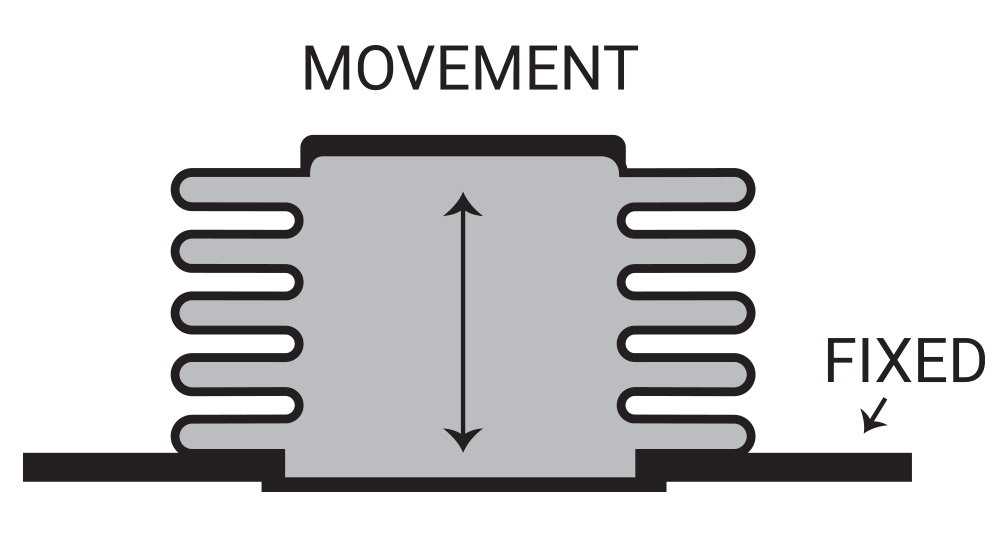

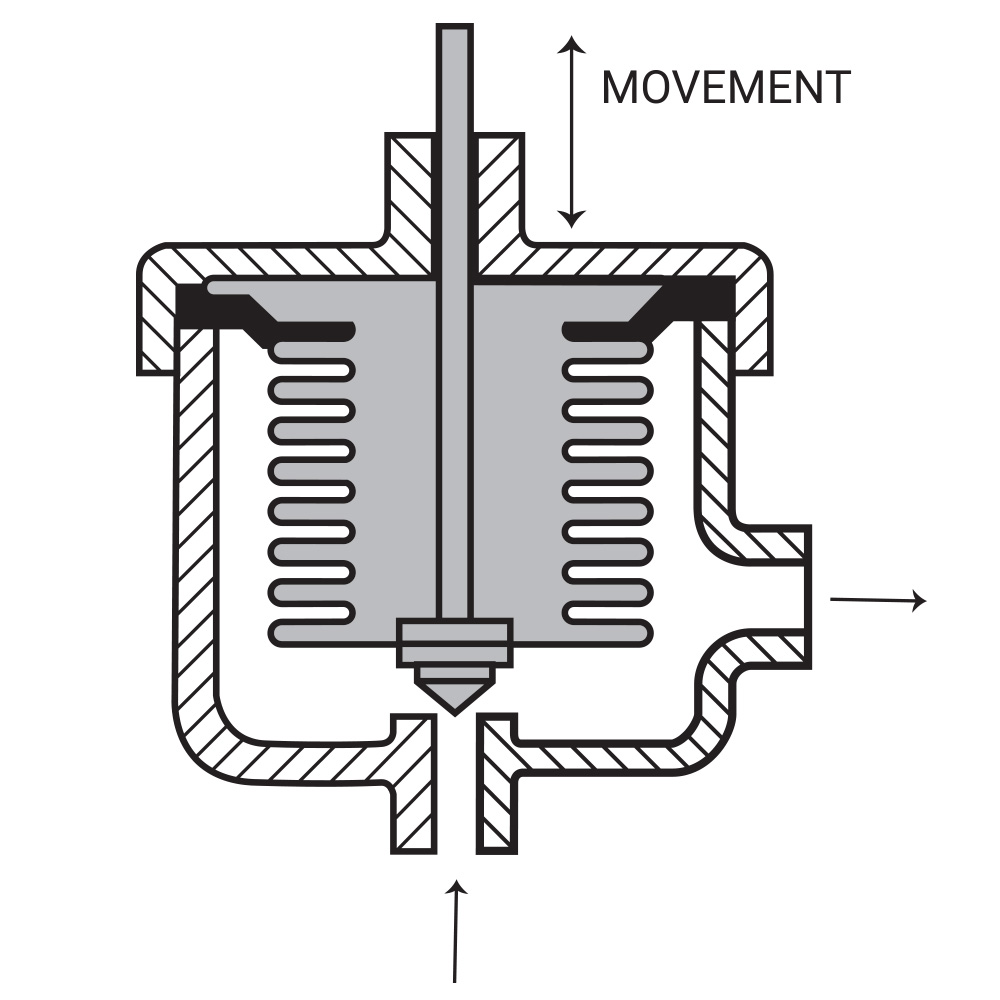

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

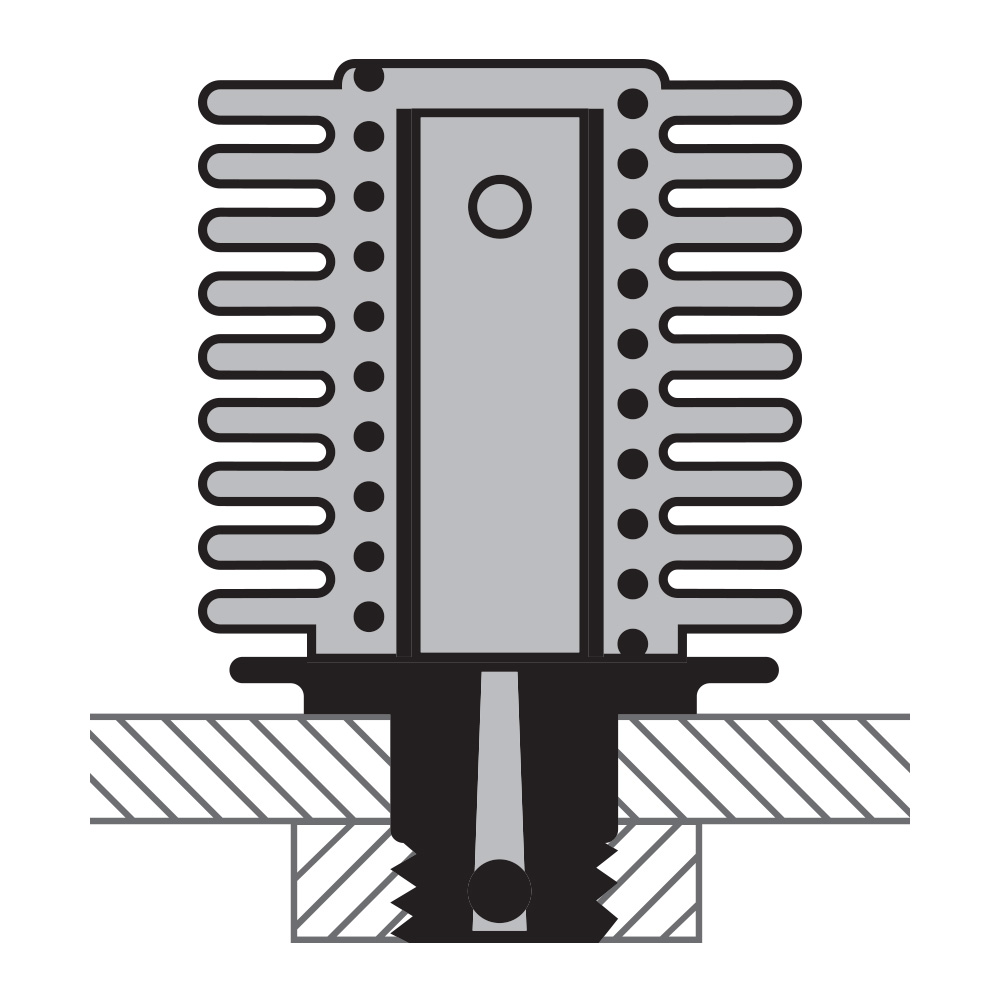

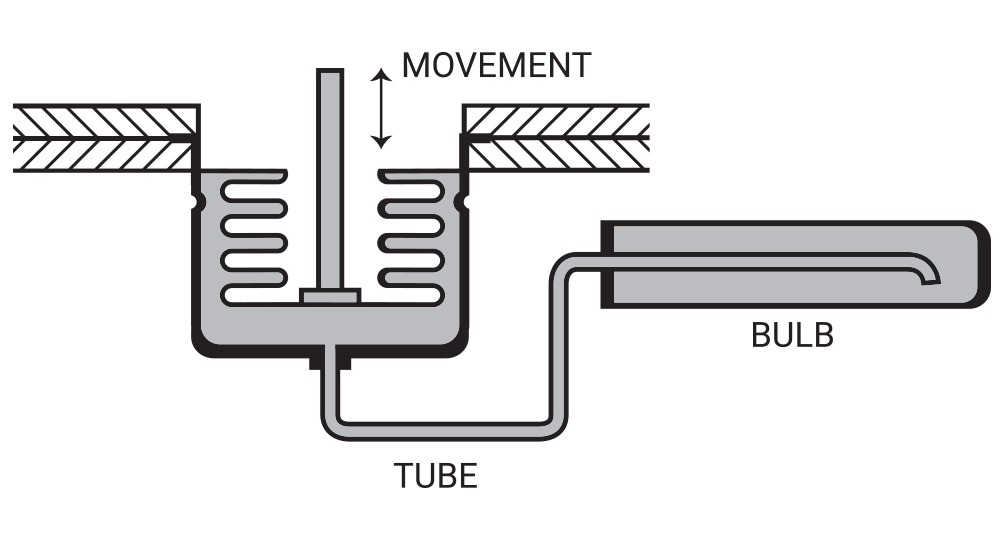

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.