Instruments & Controls

Fulton Bellows’ pressure regulators and sensors play a crucial role in instrumentation and control applications. By precisely controlling and monitoring pressure levels, our products enable efficient and accurate operation across various industries.

In industrial settings, our pressure regulators ensure that the pressure of fluids or gases remains within the desired range, preventing equipment damage and ensuring optimal performance. Whether it’s controlling pressure in manufacturing processes, hydraulic systems, or pneumatic applications, our regulators deliver reliable and consistent results.

Complementing our pressure regulators, Fulton Bellows’ pressure sensors offer real-time pressure monitoring, providing valuable data for process control and system optimization. By accurately measuring pressure levels, these sensors enable operators to maintain optimal conditions and respond promptly to any deviations or abnormalities, ultimately enhancing safety and efficiency in critical operations.

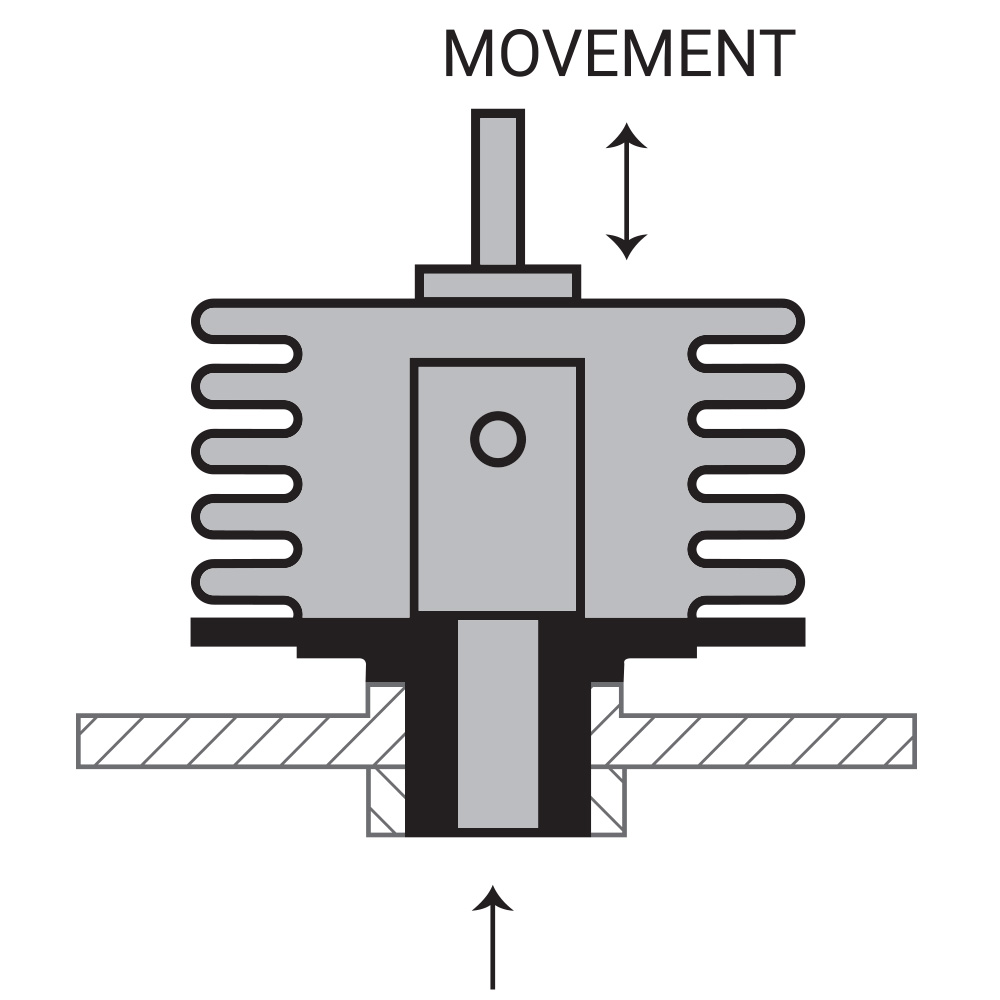

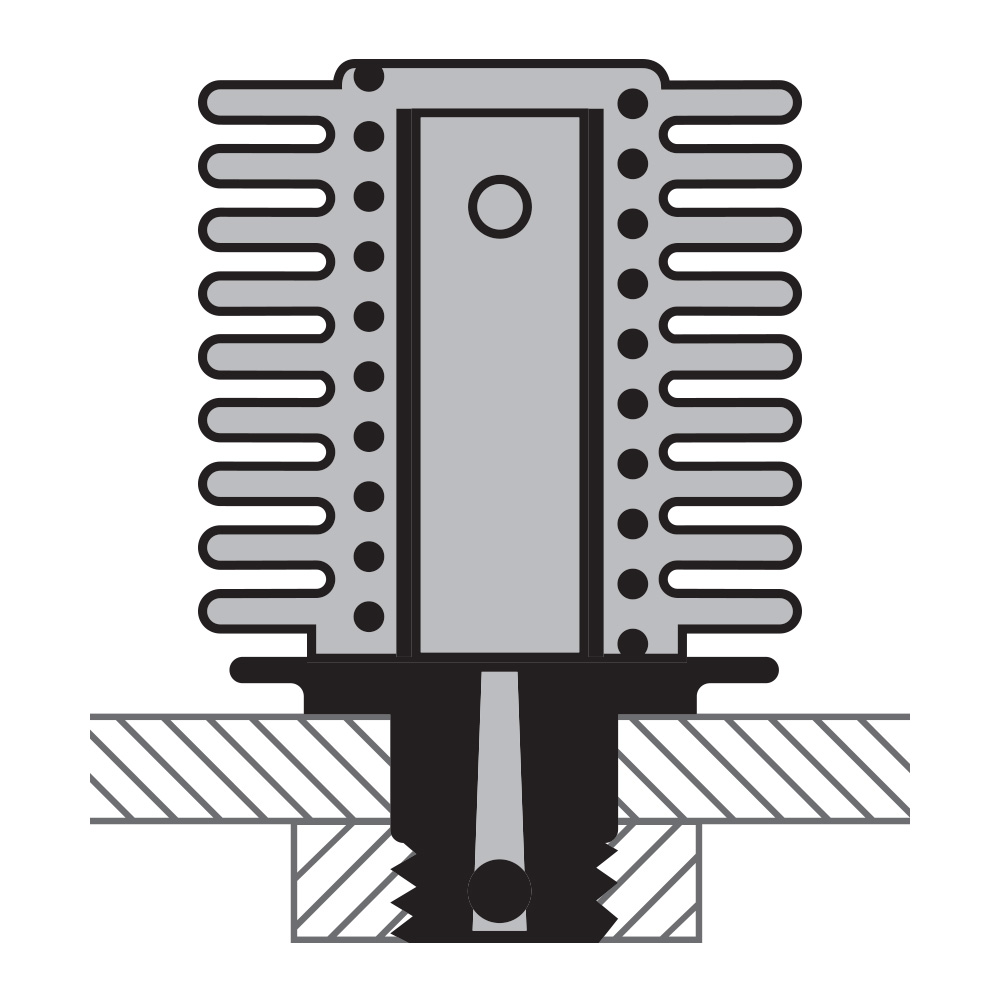

In one remarkable aircraft application, Fultons’ bellows play a vital role in protecting load-cell electronics. The bellows act as a flexible cover over the load-cell device, which senses the weight of the aircraft through the landing gear before departure. The bellows’ mission is twofold: to hermetically seal and shield the load-cell electronics from environmental contamination, while remaining flexible to accommodate the dynamic movements of the aircraft.

By providing a robust and flexible seal, our bellows prevent moisture, dust, and other contaminants from compromising the load-cell electronics’ integrity. The hermetic sealing ensures accurate weight sensing and reliable performance, safeguarding critical data for safe aircraft operations.

Basic and Common Applications

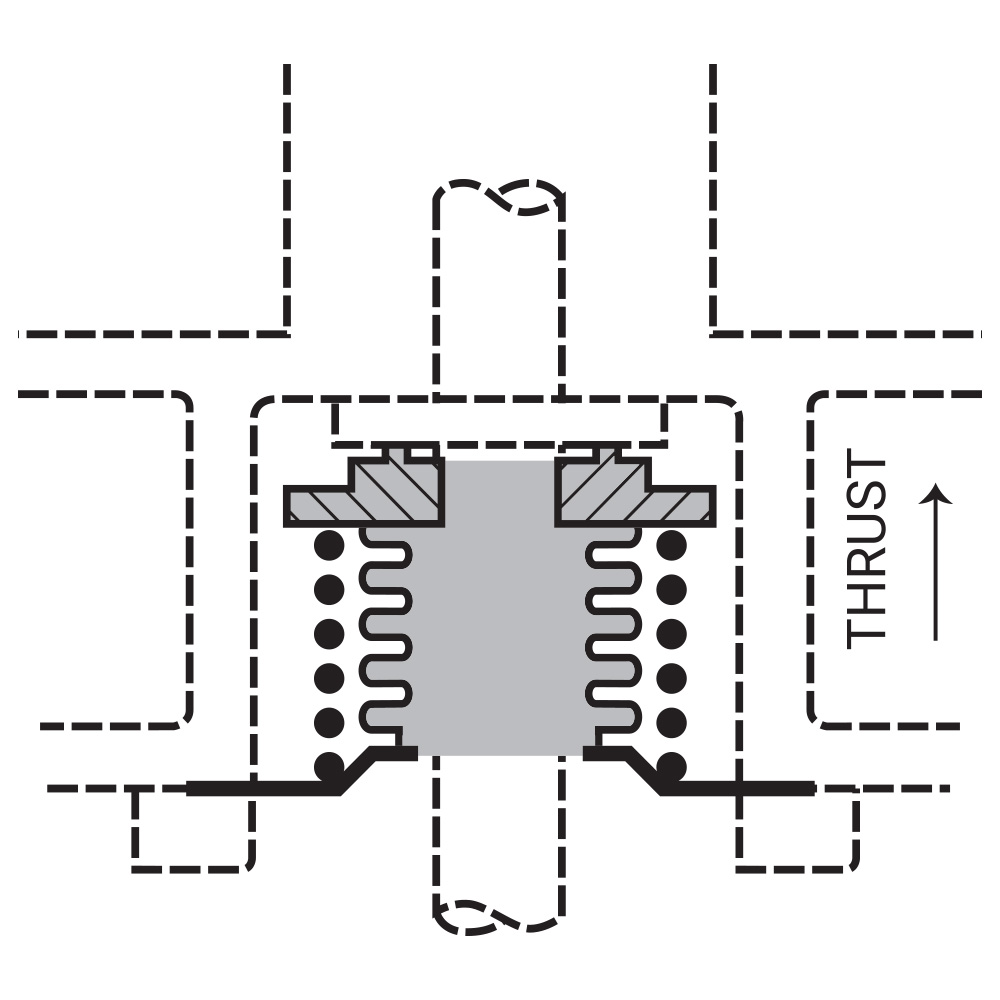

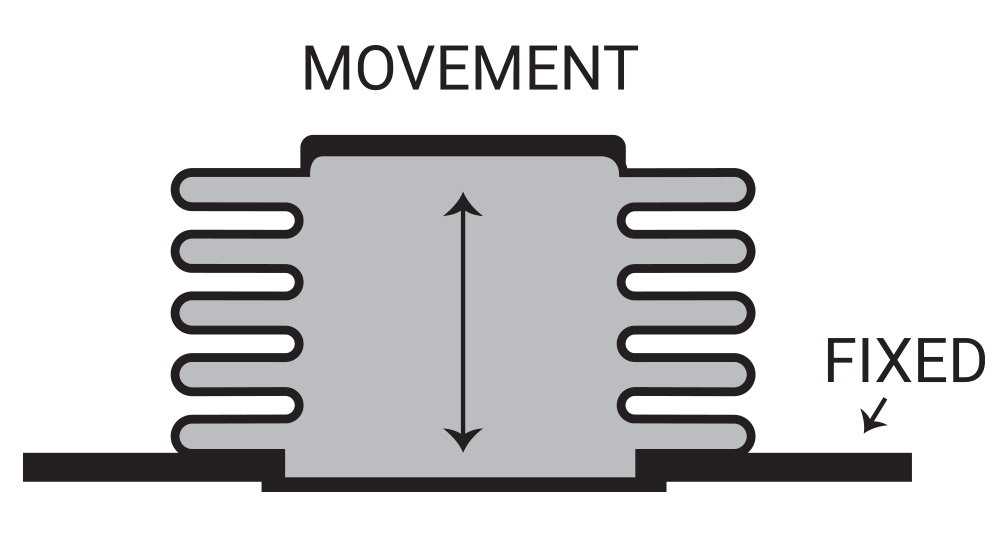

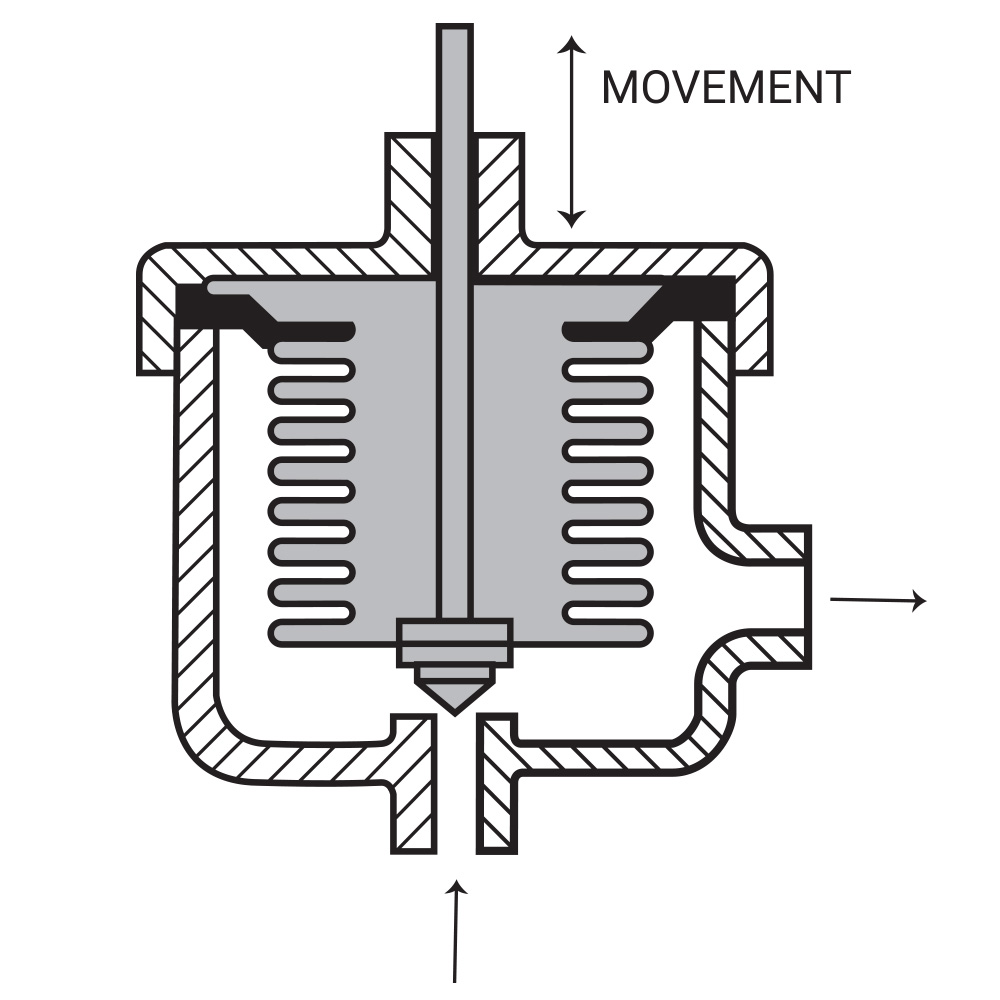

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

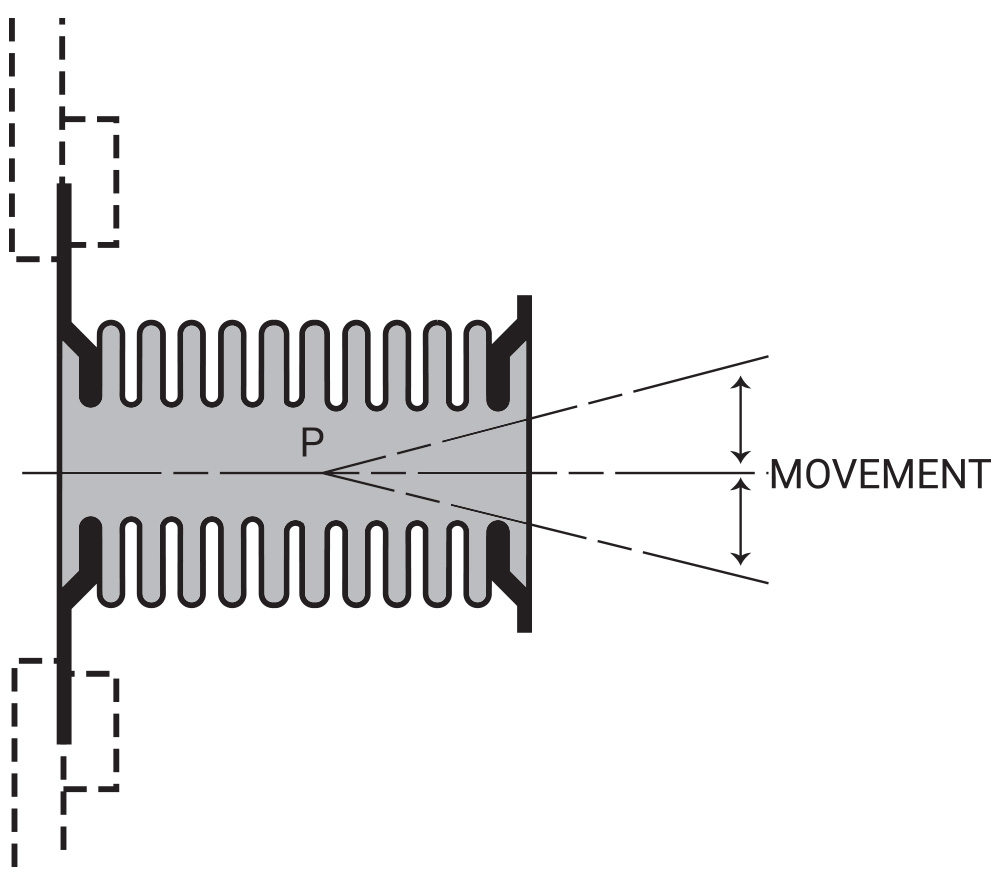

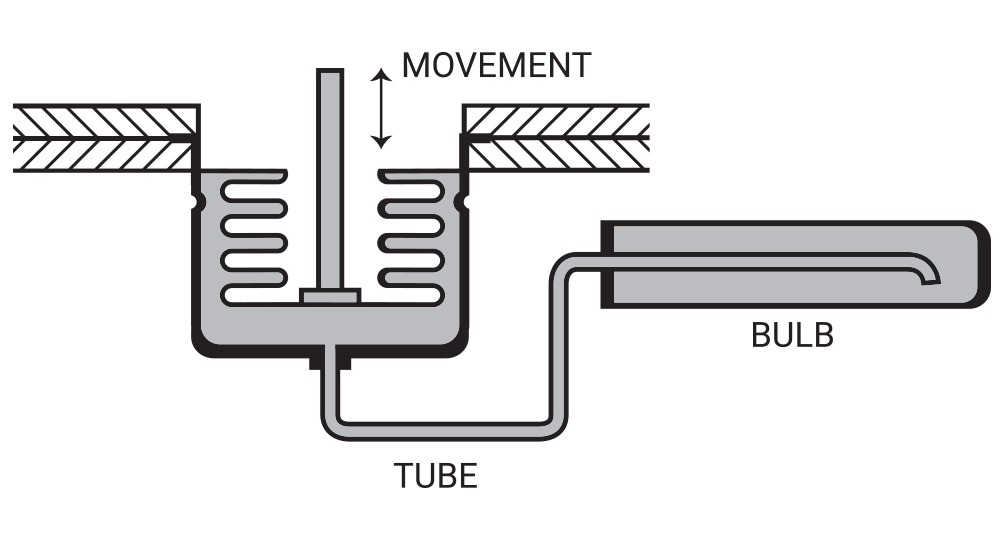

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.