Alternative Fuels

Fulton Bellows has emerged as a trusted partner in the field of alternative fuel applications. Our advanced products find diverse applications in industries transitioning towards cleaner and more sustainable fuel sources.

Fulton Bellows is at the forefront of the transition towards cleaner energy sources, including alternative fuels. Our bellows technology plays a pivotal role in supporting the efficient and reliable operation of various alternative fuel systems. By providing flexible and durable solutions, we contribute to the advancement of sustainable energy solutions that reduce reliance on fossil fuels.

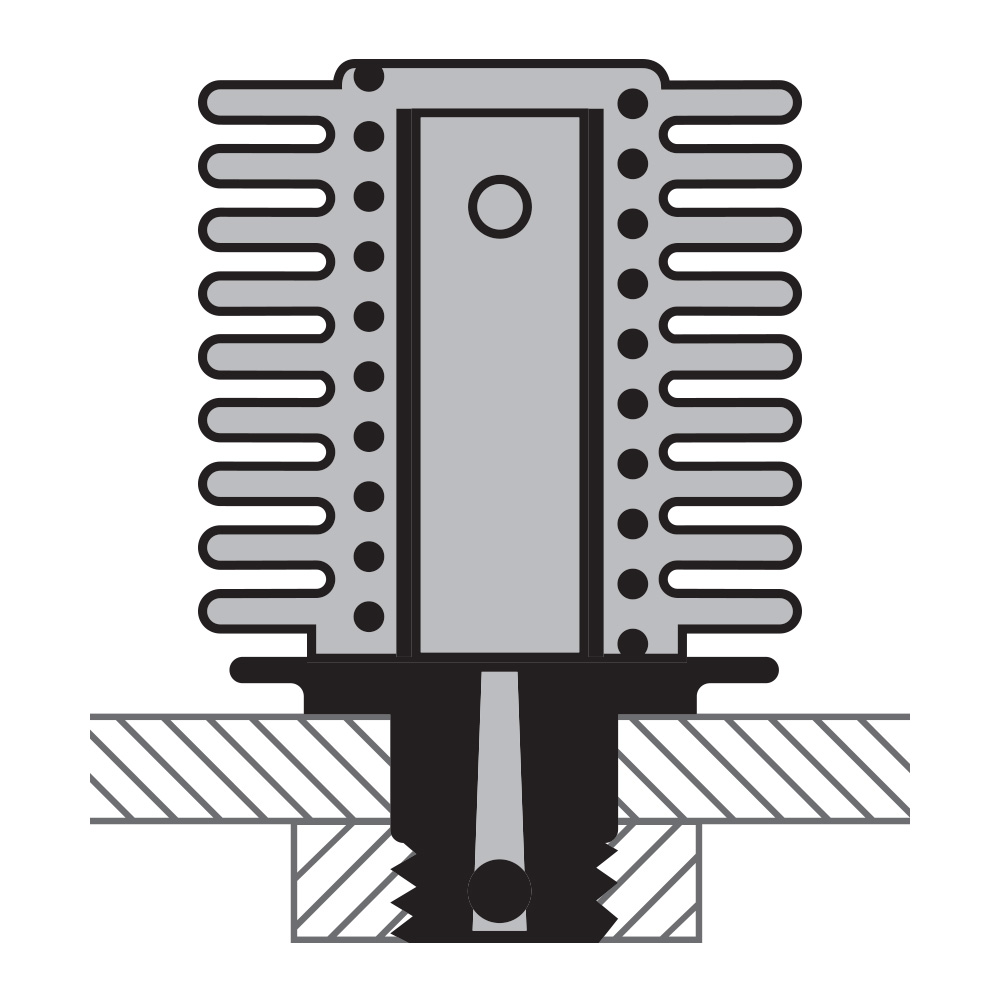

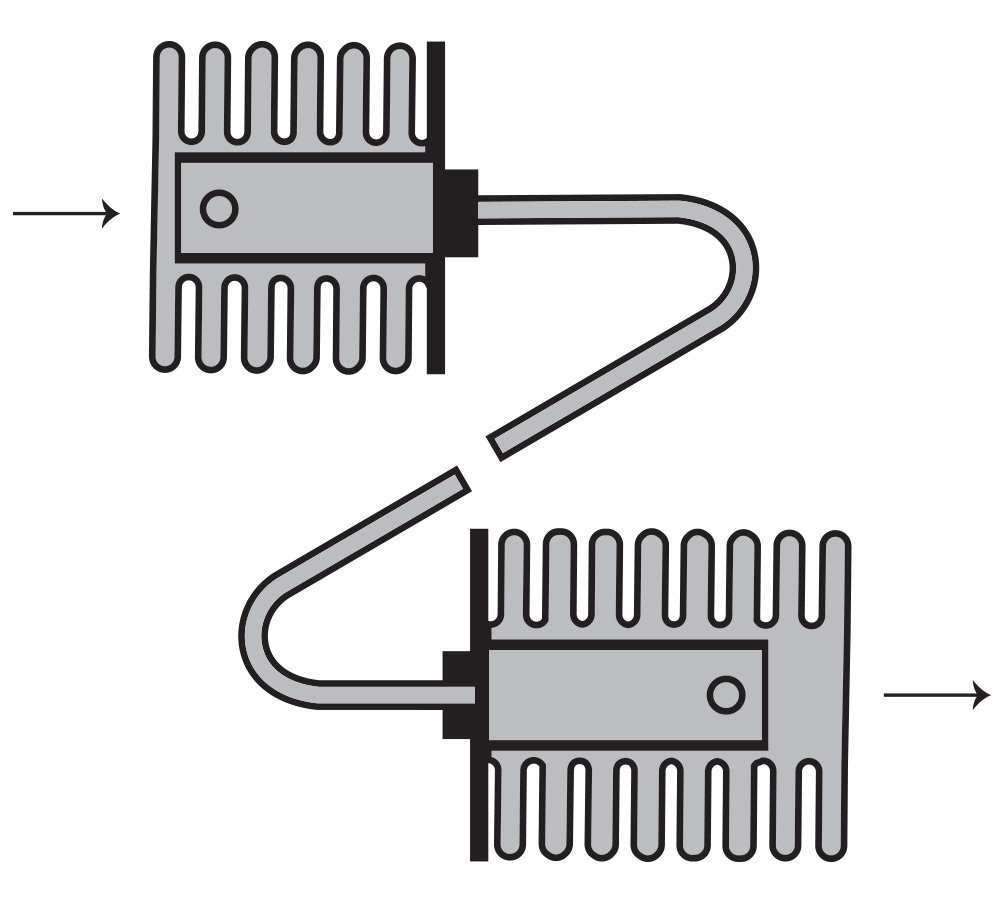

Fuel cells are a promising technology in the alternative fuel sector, and Fulton Bellows is actively involved in the development bellows assemblies that are integral to the performance and functionality of fuel cells. These assemblies provide critical sealing and flexible coupling capabilities, allowing for the controlled flow of fuel and ensuring optimal energy conversion.

In alternative fuel applications, the precise control of fluid flow is essential. Fulton Bellows’ thermal actuators play a crucial role in regulating valves within alternative fuel systems. These actuators respond to temperature changes, enabling accurate modulation of fuel flow rates. By facilitating optimal fuel delivery, our thermal actuators contribute to the efficiency and stability of alternative fuel combustion processes.

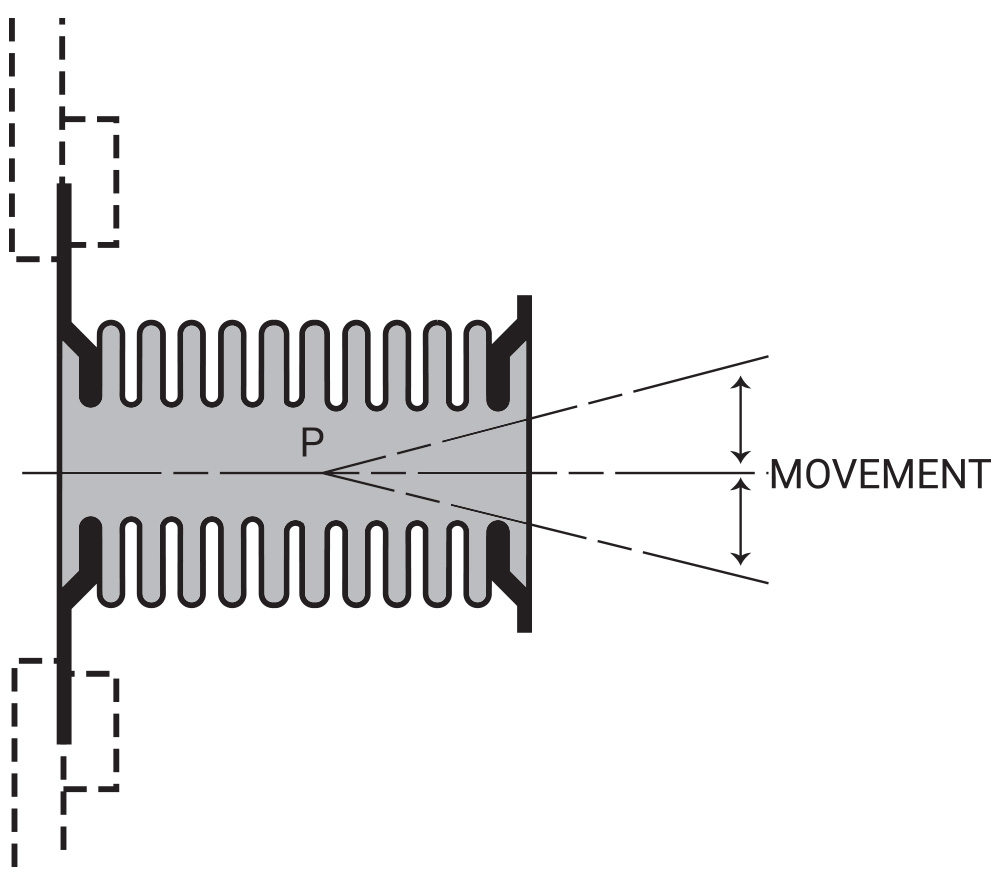

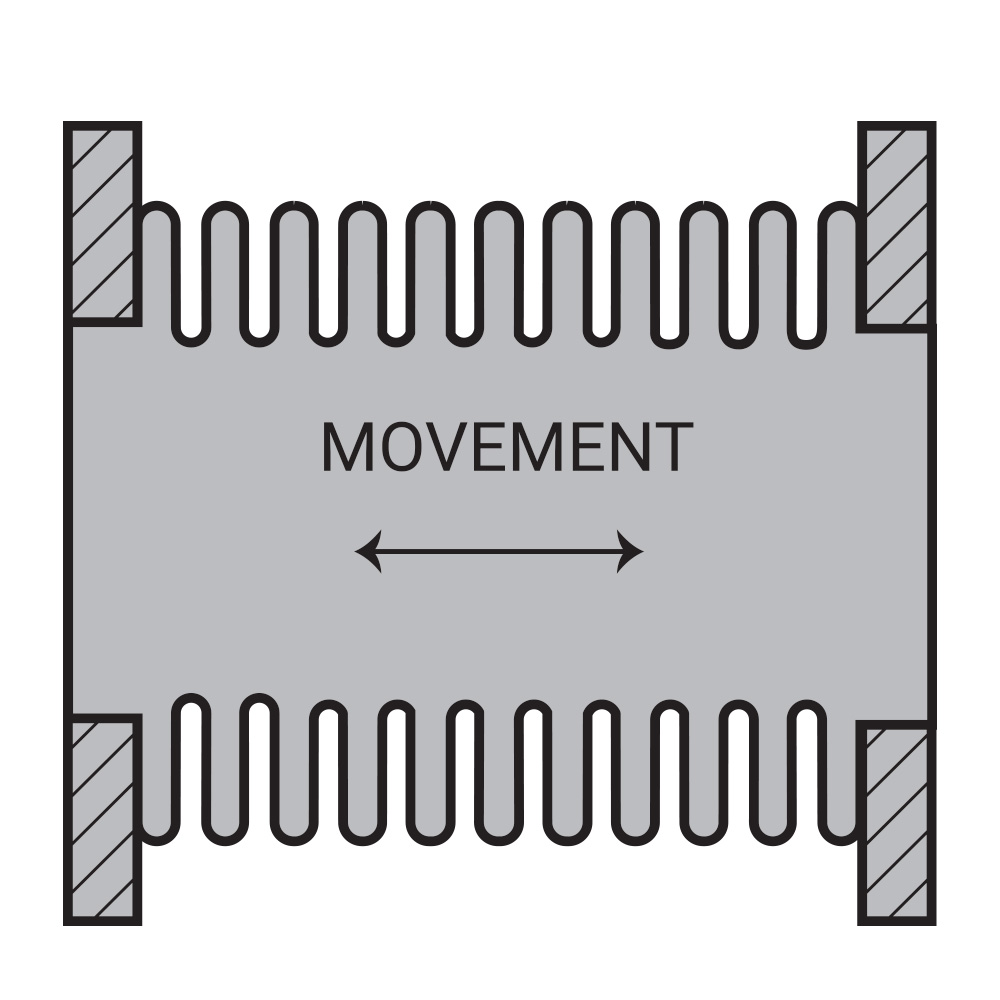

Fulton Bellows supports the storage and transportation of alternative fuels by providing bellows solutions tailored to specific requirements. Fultons’ bellows ensure the reliable and safe containment of these substances. Our expertise in flexible coupling design and hermetic sealing allows for the expansion and contraction of storage containers, maintaining the integrity of alternative fuels during storage and transportation.

By offering specialized bellows assemblies for fuel cells, thermal actuators for alternative fuel valves, and reliable bellows for storage and transportation, we contribute to the efficient and sustainable utilization of alternative fuel sources.

Basic and Common Applications

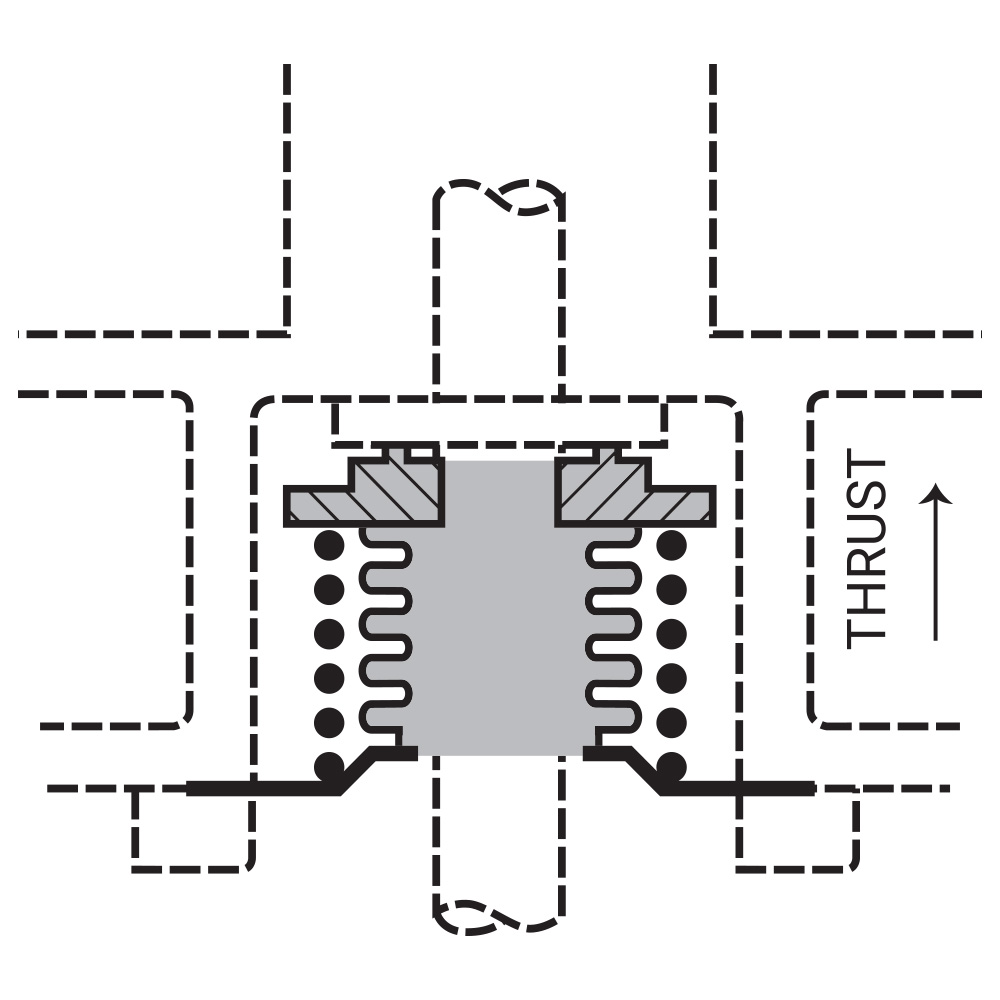

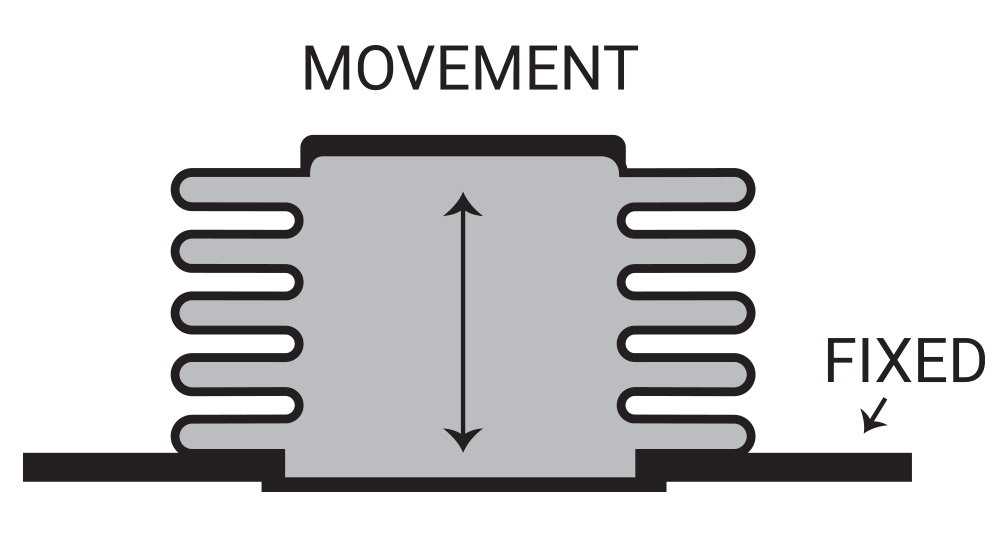

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

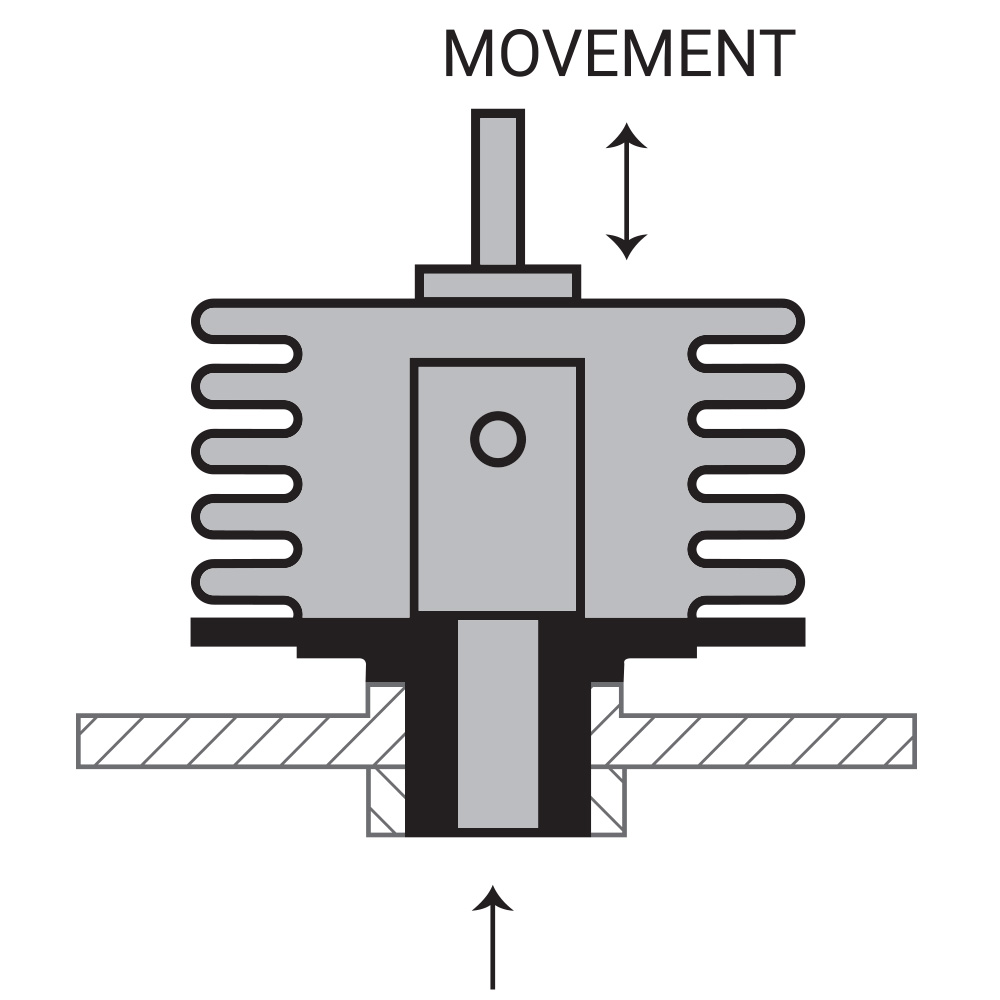

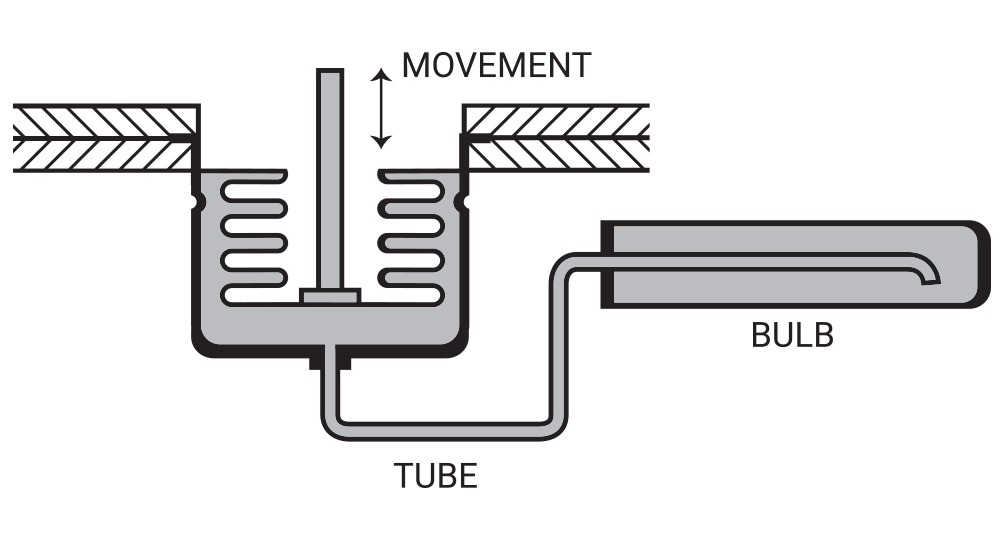

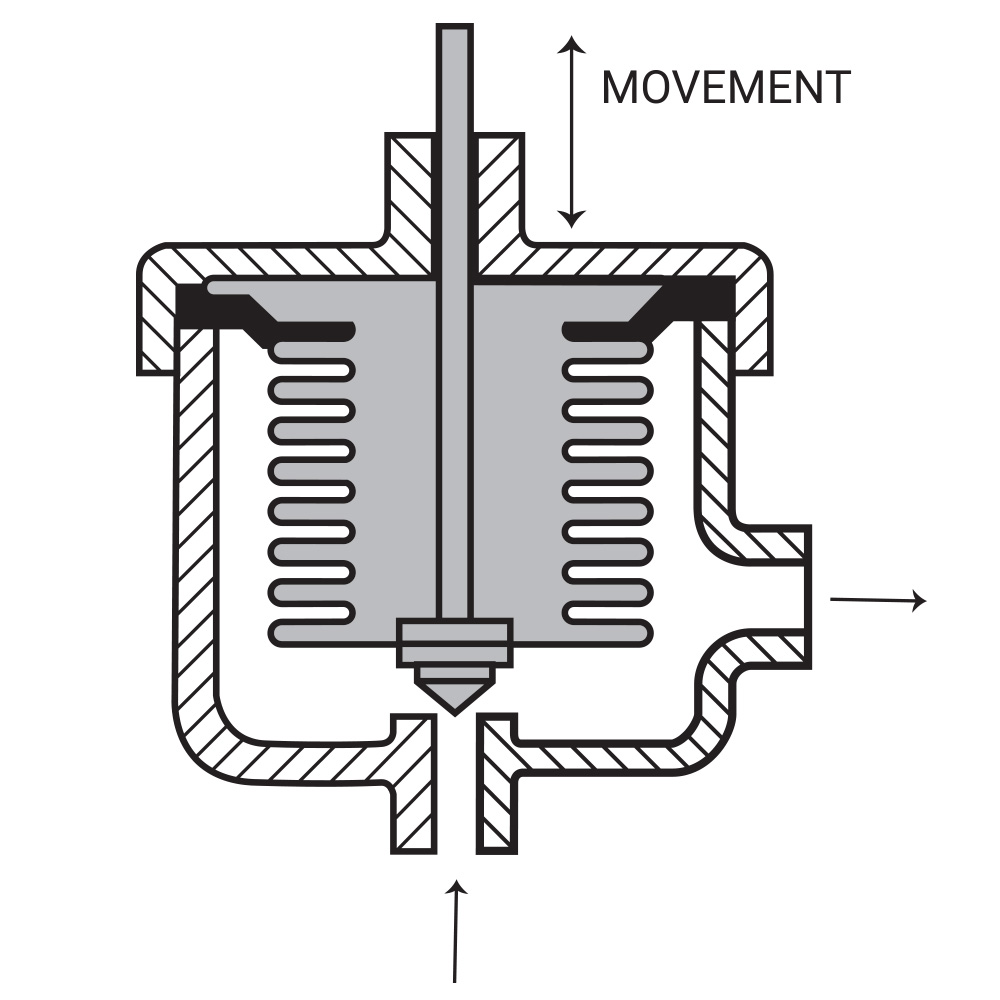

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.