Aerospace

At Fulton Bellows, we specialize in designing and building high-quality bellows and bellows assemblies for a wide range of aerospace applications. With our extensive experience and commitment to excellence, we have established ourselves as a trusted partner in the aerospace industry.

One of our notable achievements includes the production of a bellows assembly utilized in a pressure regulator responsible for controlling the flow of gases in satellite propulsion systems. This critical component has demonstrated exceptional performance, proving its robustness, reliability, and consistency within the system. Designed to meet the rigorous demands of the spacecraft, our bellows assembly consistently operates within the required range, ensuring the spacecraft’s critical performance.

Fulton Bellows has also designed, developed, and manufactured various aneroid bellows assemblies tailored to meet the diverse needs of our aerospace customers. These assemblies adhere to the strictest requirements and are deployed in critical areas of the aircraft, such as fuel control and pilot environmental controls. By effectively controlling fluids like fuel or oxygen, our aneroid bellows assemblies contribute to the optimal functioning and safety of the aircraft.

Our expertise extends beyond fuel and fluid control applications. Fulton Bellows manufactures bellows assemblies utilized as V-seals or in rocket propulsion systems to ensure fuel and gas retention during temperature changes. These specialized assemblies play a vital role in maintaining the integrity and efficiency of critical aerospace systems.

We also manufacture bellows specifically designed for aircraft oxygen regulators. These bellows play a crucial role in controlling the pressure and flow of oxygen, ensuring the well-being of passengers and crew. In the event of cabin pressure loss on corporate business jets, our bellows facilitate oxygen flow to passenger service units and drop-down masks, contributing to the safety and comfort of all on board.

Fulton Bellows takes pride in providing solutions for military aircraft as well. Our bellows assemblies have been utilized in the canopy opening mechanism of military aircraft, showcasing our ability to meet stringent requirements and contribute to the reliable operation of essential aircraft systems.

When it comes to aerospace applications, Fulton Bellows is the partner you can rely on. Our dedication to delivering high-quality bellows and bellows assemblies, combined with our commitment to meeting and exceeding industry standards, has made us a trusted choice among aerospace customers worldwide.

Basic and Common Applications

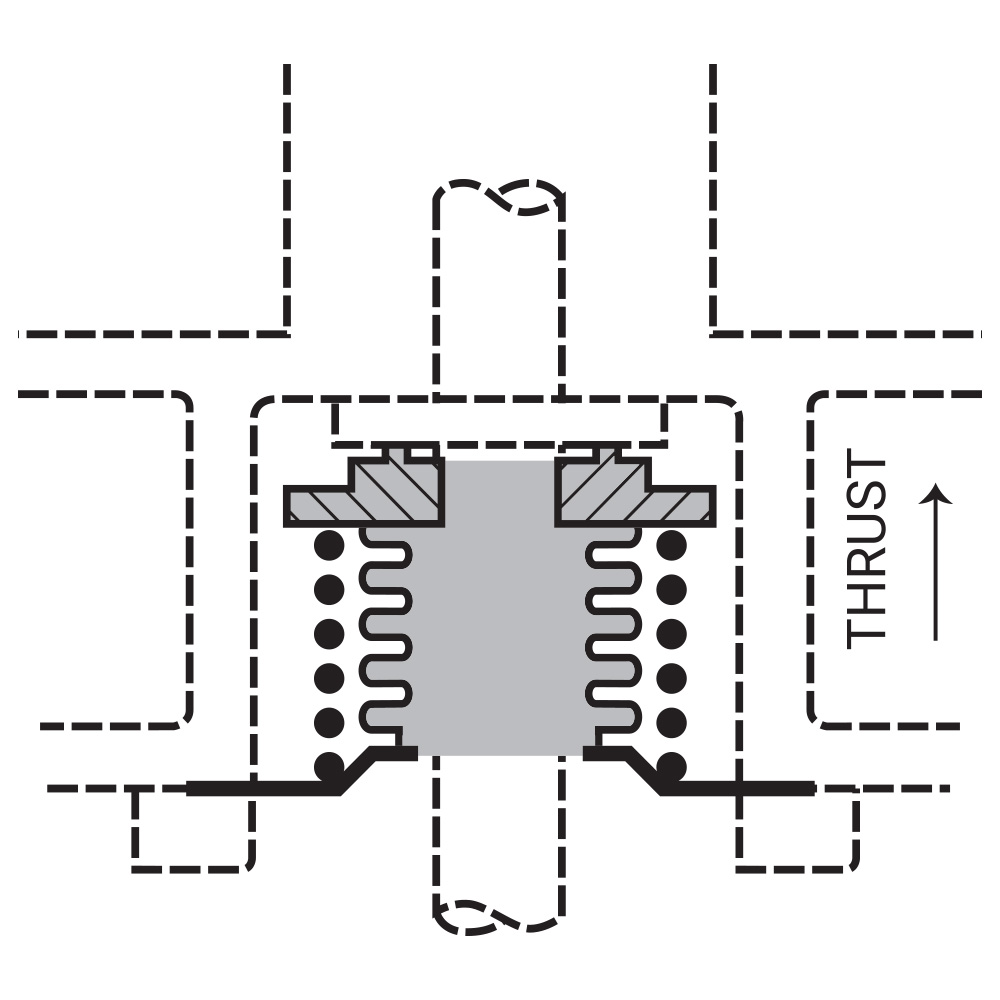

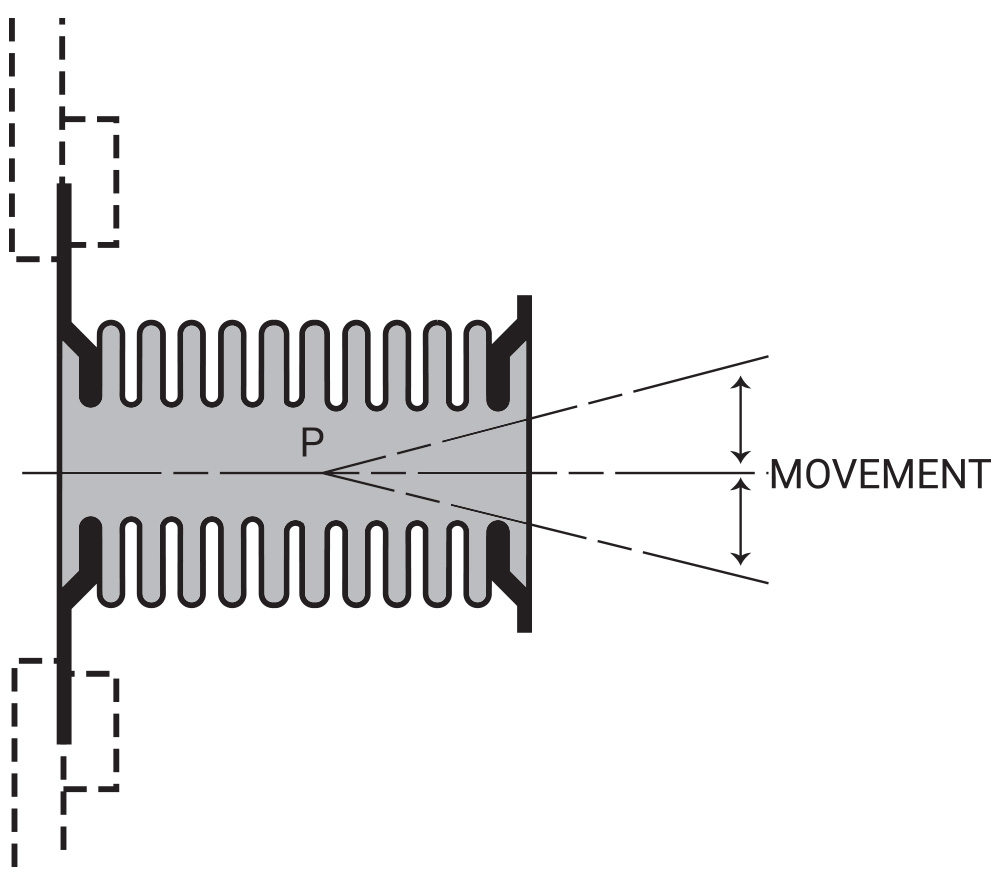

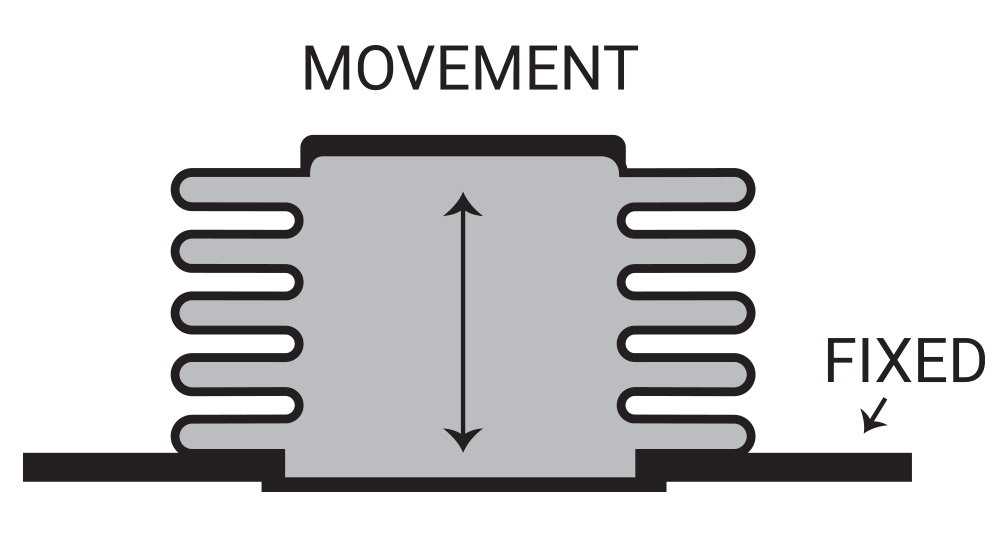

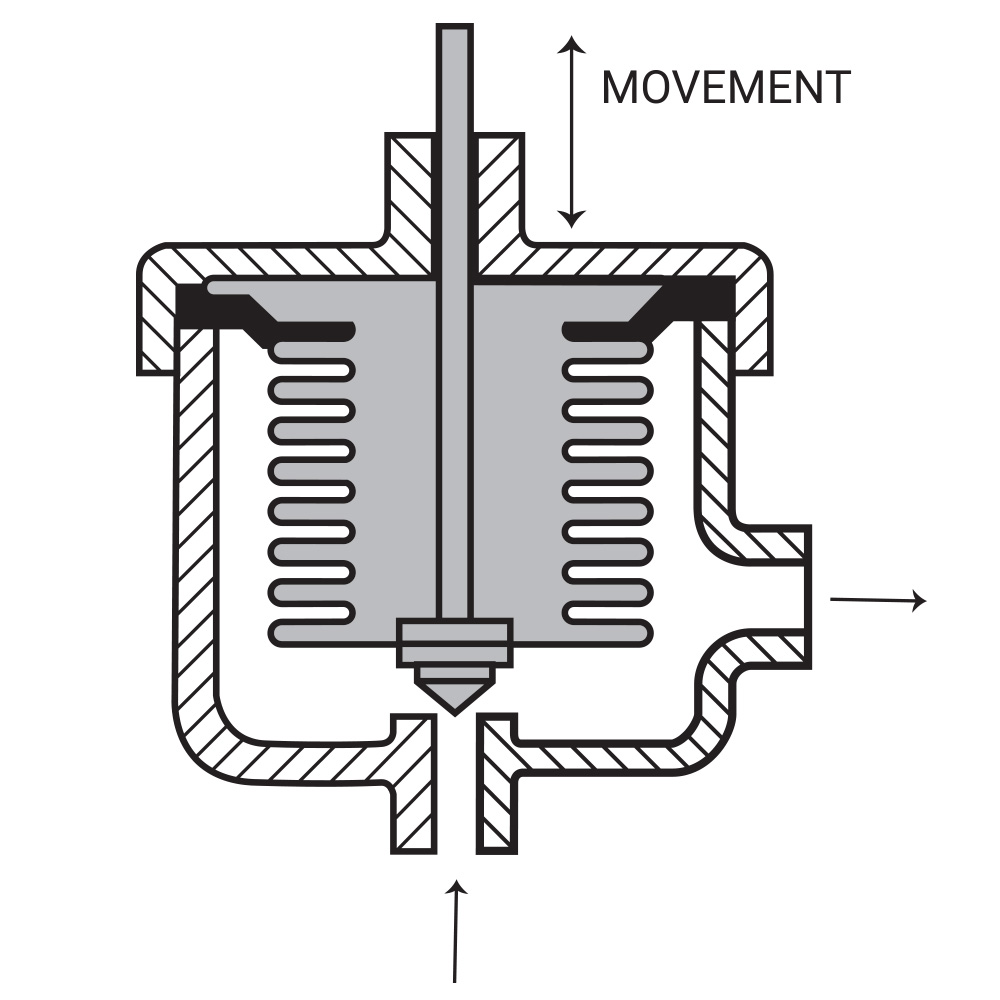

An aneroid assembly is a pressure motor where one side of a bellows assembly (inside the assembly illustrated) is evacuated to form a constant reference pressure against which the changing pressure on the other side is measured and used to produce predictable stroke. A spring for rate control and a stop to prevent excessive stroke from the resulting one atmosphere pressure differential usually are required.

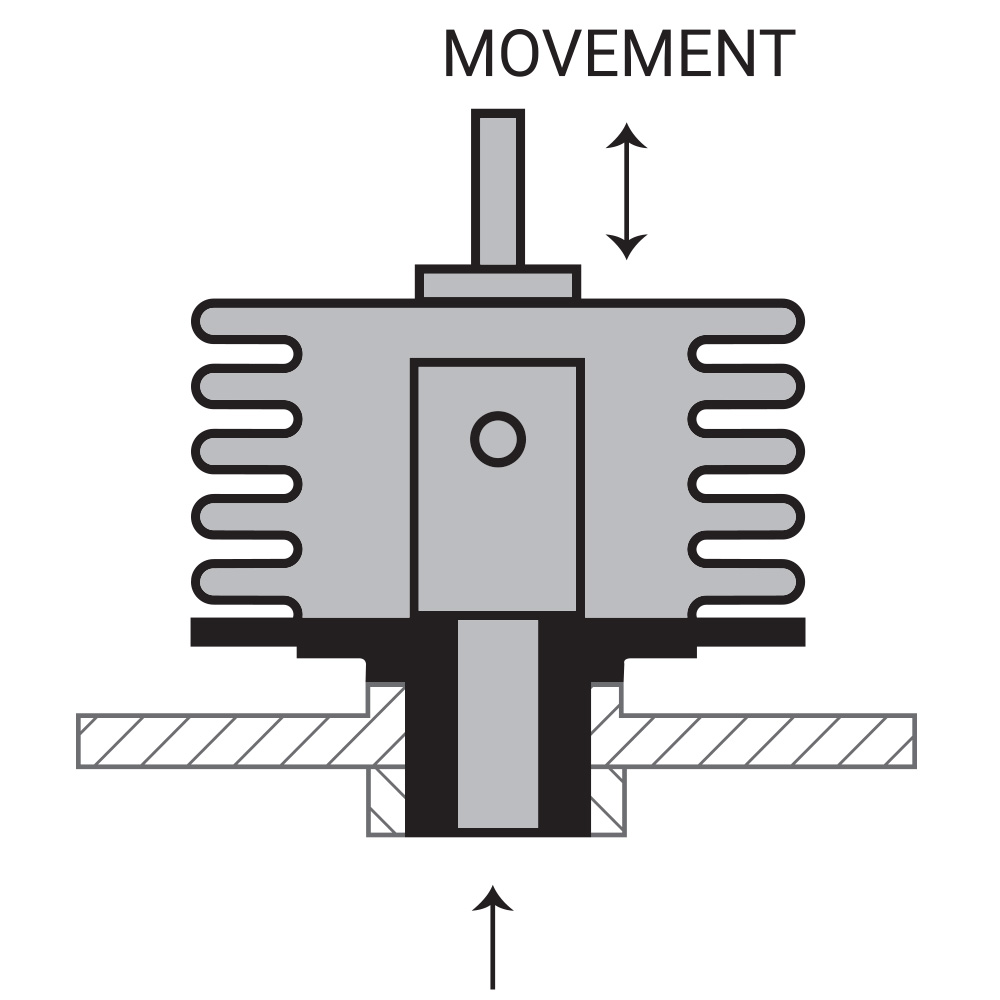

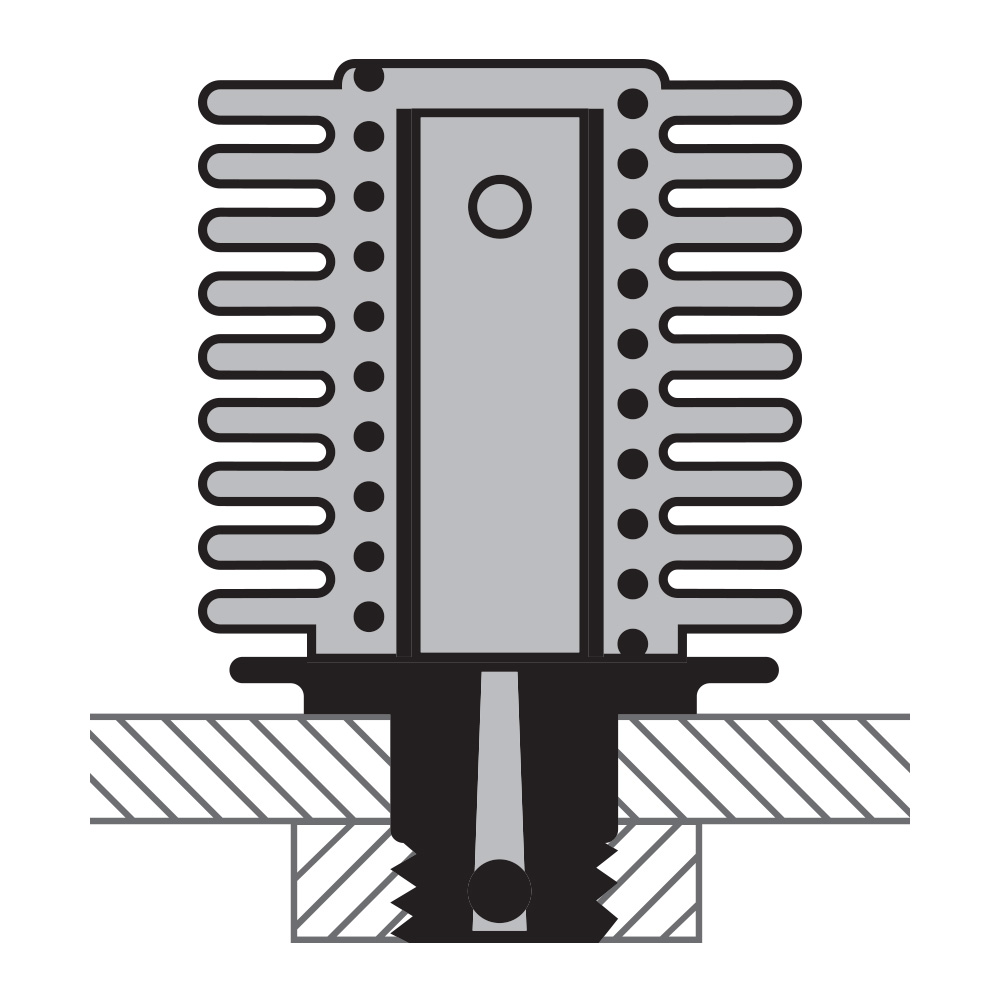

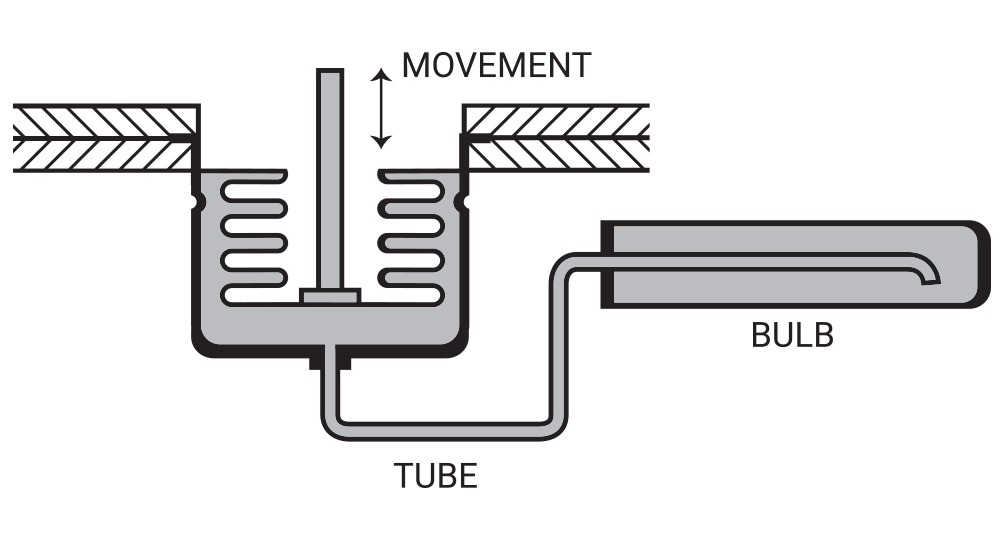

Similar to pressure motors. Pressure supplied by a sealed fill of thermo-sensitive liquid or gas. Thermal effect may be received either on the bellows element direct or at a remote bulb for transmission through flexible tubing. Widely used to operate valves, switches, etc., in response to temperature changes.