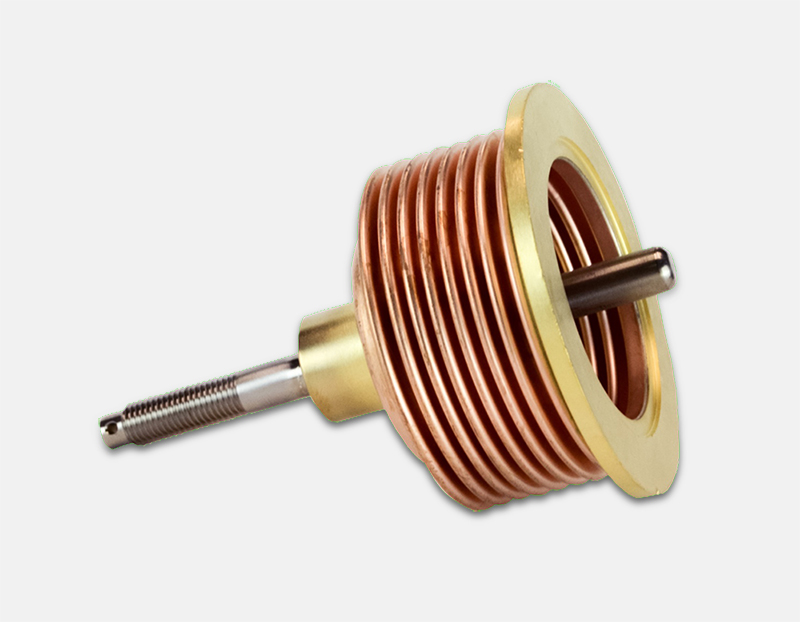

Offering Unique Expertise in the Manufacture of Bellows Assemblies

Specialized welding, brazing and soldering techniques are used to join components without endangering the expected life of the bellows. We pioneered the development and application of expansive fill materials. Extensive heat-treating equipment has been developed to ensure predictable life and consistent performance of assemblies. This broad background of technological and production capabilities has made Fulton Bellows a leading supplier of precision bellows and bellows assemblies for industry. We can bring this capability to bear to serve you in design, application engineering, and the fabrication of precision bellows or assemblies.

Capabilities

Certified Processes

Fulton Bellows is vertically integrated, allowing greater flexibility in the manufacturing of bellows and bellows assemblies. From our master coils, we have the flexibility for custom seamless tube sizes. Our in-house machine shop allows us to develop and maintain all of our tooling. We have various annealing and heat-treating capabilities that permit us to process many different types of materials. We have the capability to form bellows by hydroforming or mechanically forming depending on the application. Finally, our processes allow us to form many different end and bottom configurations.